西门子 6ES7138-4CA50-1AB0 西门子 6ES7138-4CA50-1AB0 西门子 6ES7138-4CA50-1AB0

SIMATIC DP,5 电源模块 PM-E 用于 ET 200S;24V-48V DC 含诊断 5 件/包装单位

长沙玥励自动化设备有限公司(西门子系统集成商)长期销售西门子S7-200/300/400/1200PLC、数控系统、变频器、人机界面、触摸屏、伺服、电机、西门子电缆等,并可提供西门子维修服务,欢迎来电垂询

联系人:姚善雷 (销售经理)

手机 :13874941405

QQ : 3464463681

地址:长沙市岳麓区雷锋大道468号金科世界城16-3303室

| 产品 | ||||||||||||||||||||||||||||||||||||||||

| 商品编号(市售编号) | 6ES7138-4CA50-1AB0 | |||||||||||||||||||||||||||||||||||||||

| 产品说明 | SIMATIC DP,5 电源模块 PM-E 用于 ET 200S;24V-48V DC 含诊断 5 件/包装单位 | |||||||||||||||||||||||||||||||||||||||

| 产品家族 | 电子模块的 PM-E 电源模块 | |||||||||||||||||||||||||||||||||||||||

| 产品生命周期 (PLM) | PM300:有效产品 | |||||||||||||||||||||||||||||||||||||||

| 价格数据 | ||||||||||||||||||||||||||||||||||||||||

| 价格组 / 总部价格组 | AL / 250 | |||||||||||||||||||||||||||||||||||||||

| 列表价(不含增值税) | 显示价格 | |||||||||||||||||||||||||||||||||||||||

| 您的单价(不含增值税) | 显示价格 | |||||||||||||||||||||||||||||||||||||||

| 金属系数 | 无 | |||||||||||||||||||||||||||||||||||||||

| 交付信息 | ||||||||||||||||||||||||||||||||||||||||

| 出口管制规定 | AL : N / ECCN : N | |||||||||||||||||||||||||||||||||||||||

| 工厂生产时间 | 10 天 | |||||||||||||||||||||||||||||||||||||||

| 净重 (Kg) | 0.181 Kg | |||||||||||||||||||||||||||||||||||||||

| 产品尺寸 (W x L X H) | 未提供 | |||||||||||||||||||||||||||||||||||||||

| 包装尺寸 | 8.10 x 9.10 x 6.30 | |||||||||||||||||||||||||||||||||||||||

| 包装尺寸单位的测量 | CM | |||||||||||||||||||||||||||||||||||||||

| 数量单位 | 1 包装 | |||||||||||||||||||||||||||||||||||||||

| 包装数量 | 5 | |||||||||||||||||||||||||||||||||||||||

| 其他产品信息 | ||||||||||||||||||||||||||||||||||||||||

| EAN | 4025515078227 | |||||||||||||||||||||||||||||||||||||||

| UPC | 662643789140 | |||||||||||||||||||||||||||||||||||||||

| 商品代码 | 85389091 | |||||||||||||||||||||||||||||||||||||||

| LKZ_FDB/ CatalogID | ST76 | |||||||||||||||||||||||||||||||||||||||

| 产品组 | 4056 | |||||||||||||||||||||||||||||||||||||||

| 原产国 | 中国 | |||||||||||||||||||||||||||||||||||||||

| Compliance with the substance restrictions according to RoHS directive | RoHS 合规开始日期: 2008.12.31 | |||||||||||||||||||||||||||||||||||||||

| 产品类别 | A: 问题无关,即刻重复使用 | |||||||||||||||||||||||||||||||||||||||

| 电气和电子设备使用后的收回义务类别 | 没有电气和电子设备使用后回收的义务 | |||||||||||||||||||||||||||||||||||||||

| 分类 | ||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

TM Count 2x24V,订货号: 6ES7550-1AA00-0AB0 是一个能够提供双通道计数、测量以及位置反馈功能的工艺模块。

图01. TM Count 2x24V 模块视图

计数是指对事件进行记录和统计,工艺模块的计数器 捕获编码器信号和脉冲,并对其进行相应的评估。可以使用编码器或脉冲信号或通过用户程序指定计数的方向。也可以通过数字量输入控制计数过程。模块内置的比 较值功能可在定义的计数值处准确切换数字量输出(不受用户程序及 CPU 扫描周期的影响)。

| 名称 | 订货号 | 版本 |

| CPU 1511 | 6ES7511-1AK00-0AB0 | FW V1.5 |

| TM 2x24V | 6ES7550-1AA00-0AB0 | FW V1.0 |

| STEP7 TIA Portal | 6ES7822-1AA03-0YA5 | V13 |

| 图例 | 名称 | 信号类型 |

|

增量编码器(A、B 相差) |

带有 A 和 B 相位差信号的增量编码器。 |

|

增量编码器(A、B、N) | 带有 A 和 B 相位差信号以及零信号 N 的增量编码器。 |

|

脉冲 (A) 和方向 (B) | 带有方向信号(信号 B)的脉冲编码器(信号 A)。 |

|

单相脉冲 (A) | 不带方向信号的脉冲编码器(信号 A)。可以通过控制接口指定计数方向。 |

|

向上计数 (A),向下计数 (B) | 向上计数(信号 A)和向下计数(信号 B)的信号。 |

表01. 计数器工艺对象支持的信号类型

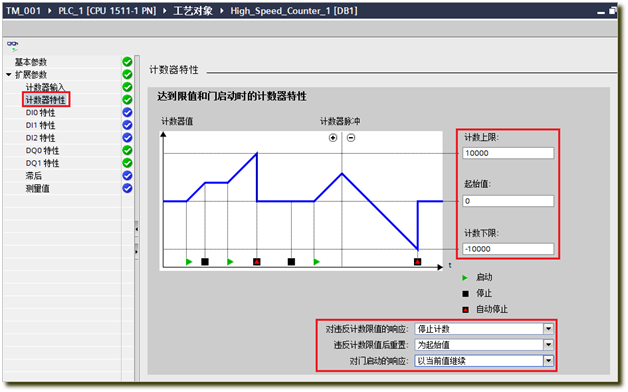

在计数器特性里面可以配置计数器的起始值,上下极限值和计数值到达极限时的状态,以及门启动时计数值的状态。在本例中设置起始值为0,上下极限为+/-10000,设置当计数值到达极限时计数器将停止,并且将计数值重置为起始值,将门功能设置为继续计数(图11)。

图11. 设置计数器的上下限及门功能

| 序号 | 名称 | 功能 |

| 1 | SwGate | 软件门:通过该控制位来控制计数器启动和停止; |

| 2 | ErrorACK | 错误应答:出现错误并处理错误后通过此控制位来复位故障状态; |

| 3 | EventACK | 事件应答:确认计数器事件状态,如:计数值超限等; |

| 4 | SetCountValue | 设置计数值:通过该控制位可以将当前计数值更改为其他值,注意:修改值需要写到工艺对象静态变量“NewCountValue”中; |

| 5 | StatusHW | 工艺模块状态位: 模块已组态并准备好运行, 模块数据有效; |

| 6 | StatusGate | 门状态位:该状态位反映了内部门的实际状态,只有改状态为为"True"时,计数器才会工作; |

| 7 | StatusUp | 增计数状态位:表示当前计数方向为增计数; |

| 8 | StatusDown | 减计数状态位:表示当前计数方向为减计数; |

| 9 | PosOverflow | 超上限状态位:表示当前计数值已经超过设定的计数值上限; |

| 10 | NegOverflow | 超下限状态位:表示当前计数值已经超过设定的计数值下限; |

| 11 | Error | 错误状态位:表示当前计数工艺对象有错误; |

| 12 | ErrorID | 错误代码:显示当前工艺对象错误的故障代码; |

| 13 | CounterValue | 计数值:计数器工艺对象的实际计数值; |

. TDC IE communication introduction

TDC system is the newest digital control system of SIMADYN D family and it has the highest quality in the SIMATIC control system family.

As one part of TIA family it has powerful communication function. The system provides the MPI communication protocol, Profibus communication protocol, Ethernet communication protocol. It is easy to communicate with other simatic product, for example S7-300, S7-400, HMI and drives product.

For Ethernet communication, the hardware platform is CP51M1 which supply a standard RJ45 Ethernet interface; the old interface CP5100 is discontinued as per Aug. 1 2005.

For communication task, system can exchange process data with other TDC system or PLC S7 system through CP51M1 module.

For communication protocol, TDC system supplies TCP/IP protocol and/or UDP protocol.

For transfer modes, refresh mode, handshake mode, multiple mode and select mode are available for selection.

For net speed it can work with 10Mbit and 100Mbit network, the module can automatically sense the net speed.

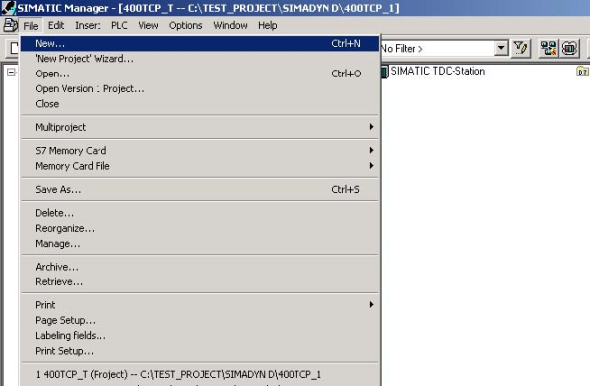

2. TDC configuration steps

2.1 Hardware configuration in SIMATIC Manager

2.1.1 Create a new S7 project

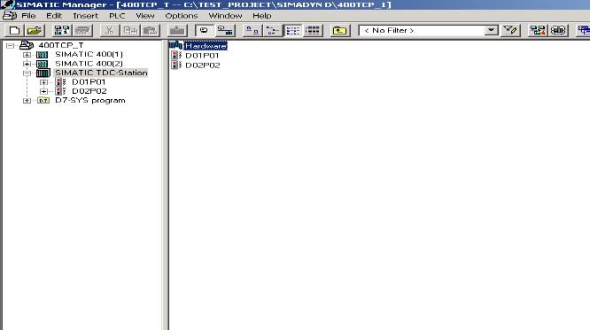

2.1.2 Insert a TDC station

2.1.3 Select hardware configuration in SIMATIC Manager, double click to open it

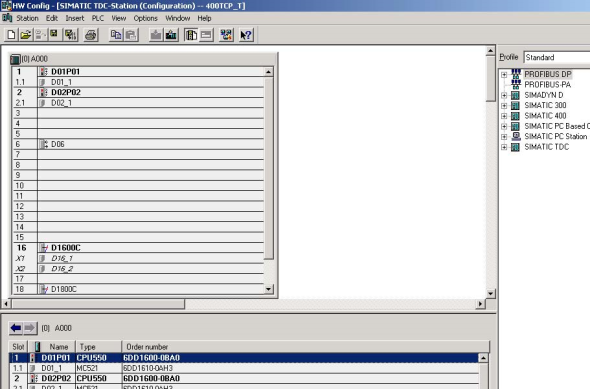

2.1.4 Insert the subrack, CPU, communication board CP51M1 and other module from the hardware catalog

Keep the same type with which is used in the sub rack.

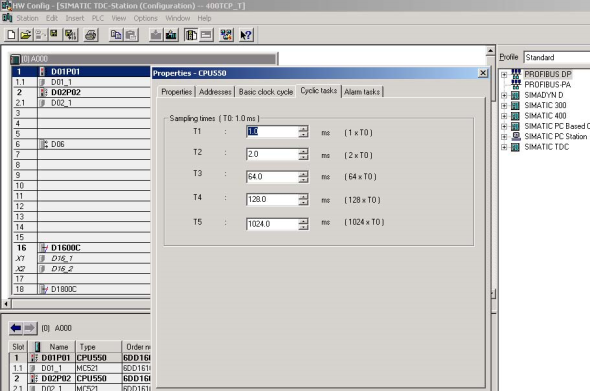

2.1.5 Define the CPU module and communication module properties

For CP51M1, we need to define the module name firstly

For Ethernet property we need to define the IP address and subnet mask

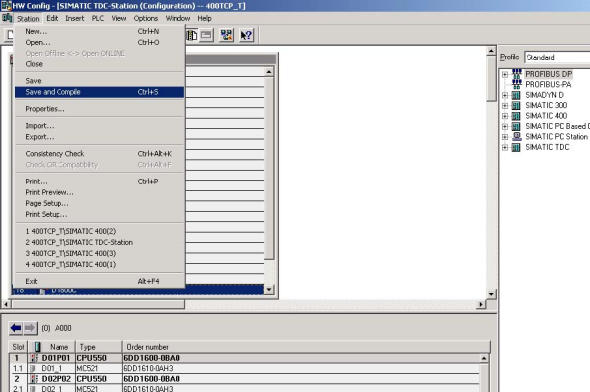

2.1.6 Save and compiled the hardware configuration

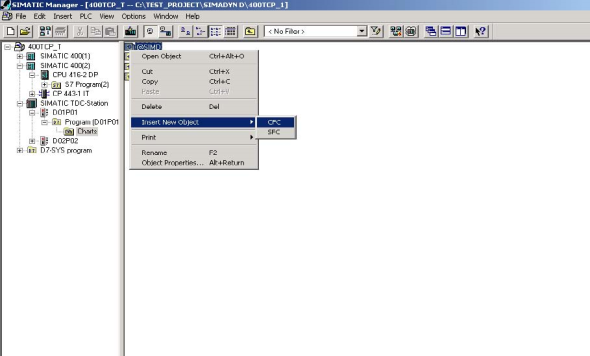

2.2 CFC programming

2.2.1 Insert a CFC program in SIMATIC Manager, double click it to open it

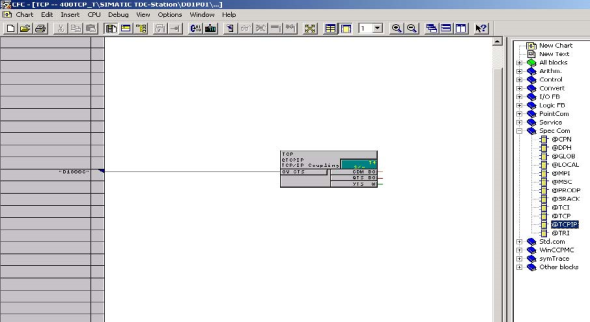

2.2.2 Insert the TCPIP communication block into the chart, define the connection address which is set in the hardware configuration and select the proper cycle time

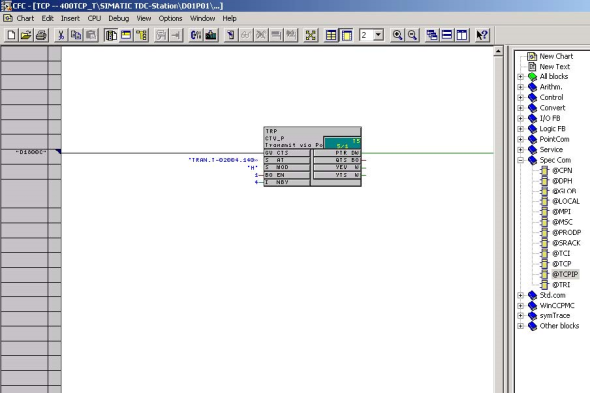

2.2.3 Insert the send function block CTV_P, define the connection:

| CTS | P51M1 hardware address which is set in hardware configuration | |||||||

| AT |

channel name.protocol type–CP51M1 port number.partner IP address–partner port number, for example: 'TRAN.T-02004.192168000003-02002’ |

|||||||

| MOD | normally we select handshake mode | |||||||

| EN | set to 1 to enable the FB | |||||||

| NBY | define the telegram length in bytes | |||||||

2.2.4 Insert the DWR_D block to write the communication content to the communication buffer

Here we can define the offset in the communication buffer by set connector1/2. The final result is the sum of offset1 and offset2.

For connector SWP we set it to 1 if it communicates with a PLC.

The data we try to send is set in connector X, here is 44 as an example.

For receive part, we can do it in the same way.

For connector AR of CRV_P, we do not need to define the partner IP address–partner port number.

2.2.5 Compiled the program and download it to the memory card and restart the system

3. S7-400 configuration steps

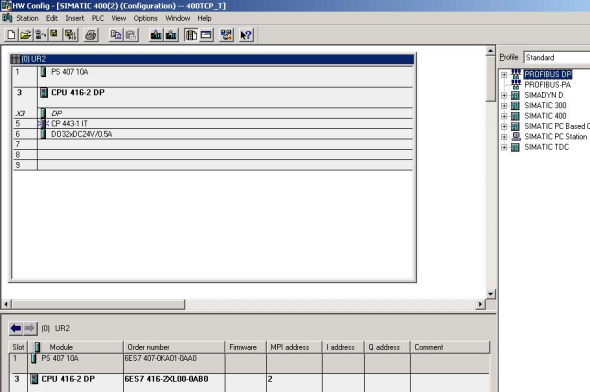

3.1 S7 hardware configuration

First insert the S7-400 station, and then open the hardware configuration to insert the modules which are available on the sub rack.

For CP443-1 module we need to define the IP address and subnet mask.

The IP address will be used in the CFC program.

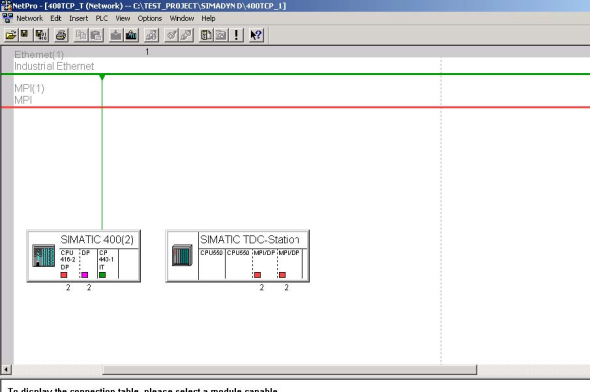

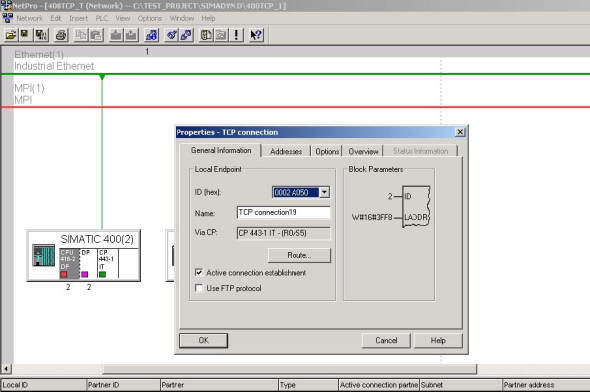

3.2 network configuration in the Netpro software

Open Netpro under hardware configuration menu

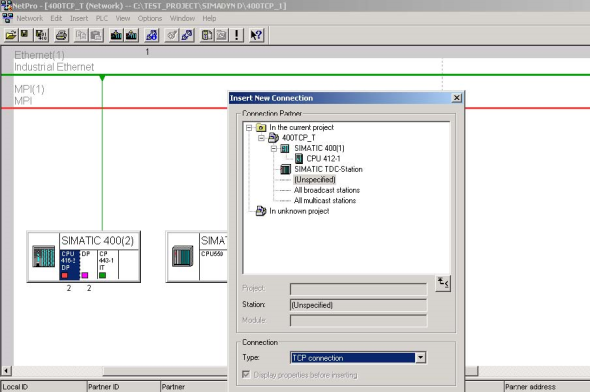

Select the CPU in the SIMATIC station and insert a new connection,

Select unspecified station and

TCP connection, press apply button.

Select the ID number, record the address LADDR.

Both of them will be used in the S7 program.

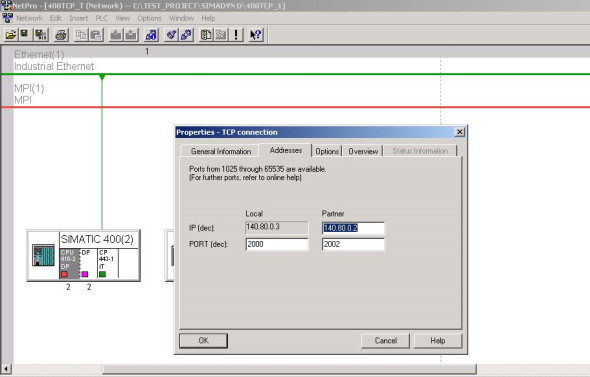

Under address menu we need to set the local port number, partner address and port number, press OK button to confirm the setting.

For other connection you need, you can do it in the same way.

Then we need to save and compile the configuration.

We need to download not only the hardware configuration, but also the Netpro configuration to the CPU.

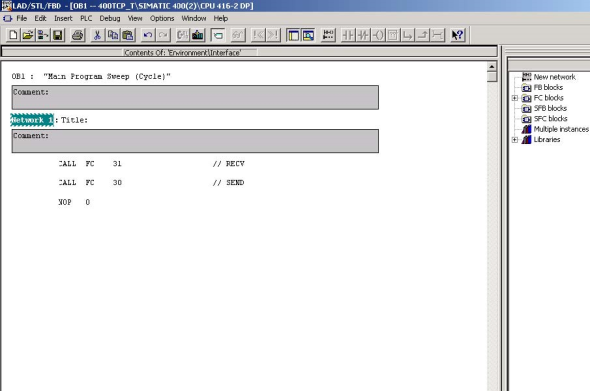

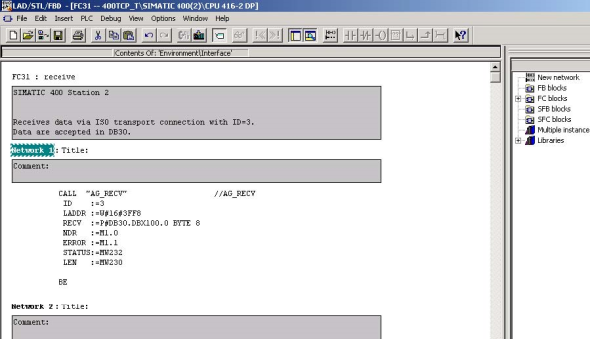

3.3 Programming in the S7 CPU

For the industrial Ethernet communication we use the FC5 AG_SEND, FC6 AG_RECV block.

These blocks transfer and receive the data on the configured TCP connection to and from the Ethernet CP.

Here we made two FC separately for send and receive function, one is FC 30 for FC5, and another is FC31 for FC6.

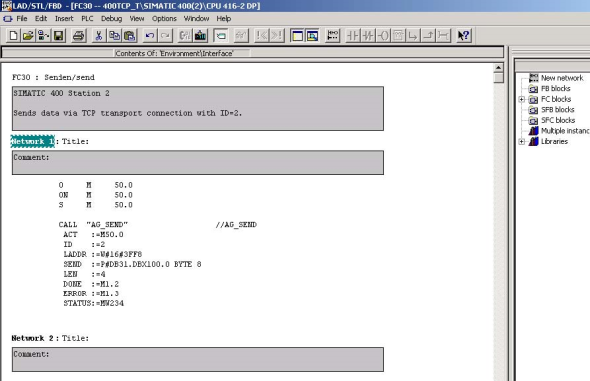

For FC5, we need to define:

| ACT: | set it to one to trigger FC | ||||||

| ID: | connection ID number which is set in Netpro | ||||||

| LADDR: | CP module start address which is set in hardware configuration, also | ||||||

| available in Netpro. The address is in HEX mode, for example 3FF8H | |||||||

| SEND: | set the transfer data address and buffer length | ||||||

| keep the format for example P#DB31.DBX100.0 BYTE 8 | |||||||

| LEN: | numbers of bytes to be send from the transport data area with this job | ||||||

| DONE: | bit signal for executed status | ||||||

For error evaluate we can check the connector Error and Status. For the status code we can get detail information in the FC5 description documentation.

For FC6, we can do it in the same way.

Because we use DB30 and DB31 in the program FC30 and FC 31, we must insert these two data block and download it to the CPU.

4. Physical connection

TDC side: CP51M1 supply RJ45 interface

S7 side: CP443-1 supply RJ45 interface

Between the double sides we need a Switch to connect.

西门子 6ES7138-4CA50-1AB0 西门子 6ES7138-4CA50-1AB0 西门子 6ES7138-4CA50-1AB0