3RW30471BB14 3RW30471BB14 3RW30471BB14

西门子MM420-12/2变频器中国授权代理商/西门子华南地区指定代理商/西门子模块代理商/西门子变频器代理商/西门子触摸屏代理商/西门子PCL200代理商/西门子PLC300代理商/西门子PCL400代理商/西门子数控伺服代理商/西门子原装授权软件代理商/西门子一级代理商

SIEMENS中国有限公司

哪里有卖 要多少钱 哪里有 哪里能买到 要在哪里买 在哪里有卖的 价格,参数,型号,哪家便宜,比较便宜,哪里有,销售,订货号,多少钱?哪家价格好? 厂家,性能,优点,包装,用途,售后服务!哪里有卖 代理商 总代理商

西门子MM420-12/2变频器中国授权代理商/西门子华南地区指定代理商/西门子模块代理商/西门子变频器代理商/西门子触摸屏代理商/西门子PCL200代理商/西门子PLC300代理商/西门子PCL400代理商/西门子数控伺服代理商/西门子原装授权软件代理商/西门子一级代理商

6ES7 963-1AA00-0AA0

拟量时,需要注意信号量程范围,拨码开关设置,模块规范接线,指示灯状态等信息。

本文中,我们按照S7-200模拟量模块类型进行分类介绍:

1.AI 模拟量输入模块

2.AO模拟量输出模块

3.AI/AO模拟量输入输出模块

4.常见问题分析

首先,请参见“S7-200模拟量全系列总览表”,初步了解S7-200模拟量系列的基本信息,具体内容请参见下文详细说明:

AI 模拟量输入模块

A. 普通模拟量输入模块:

如果,传感器输出的模拟量是电压或电流信号(如±10V或0~20mA),可以选用普通的模拟量输入模块,通过拨码开关设置来选择输入信号量程。注意:按照规范接线,尽量依据模块上的通道顺序使用(A->D),且未接信号的通道应短接。具体请参看《S7-200可编程控制器系统手册》的附录A-模拟量模块介绍。

4AI EM231模块:

首先,模拟量输入模块可以通过设置拨码开关来选择信号量程。开关的设置应用于整个模块,一个模块只能设置为一种测量范围,且开关设置只有在重新上电后才能生效。也就是说,拨码设置一经确定后,这4个通道的量程也就确定了。如下表所示:

注:表中0~5V和0~20mA(4~20mA)的拨码开关设置是一样的,也就是说,当拨码开关设置为这种时,输入通道的信号量程,可以是0~5V,也可以是0~20mA。

8AI EM231模块:

8AI的EM231模块,第0->5通道只能用做电压输入,只有第6、7两通道可以用做电流输入,使用拨码开关1、2对其进行设置:当sw1=ON,通道6用做电流输入;sw2=ON时,通道7用做电流输入。反之,若选择为OFF,对应通道则为电压输入。

注:当第6、7道选择为电流输入时,第0->5通道只能输入0-5V的电压。

B. 测温模拟量输入模块(热电偶TC;热电阻RTD):

如果,传感器是热电阻或热电偶,直接输出信号接模拟量输入,需要选择特殊的测温模块。测温模块分为热电阻模块EM231RTD和热电偶模块EM231TC。注意:不同的信号应该连接至相对应的模块,如:热电阻信号应该使用EM231RTD,而不能使用EM231TC。且同一模块的输入类型应该一致,如:Pt1000和Pt100不能同时应用在一个热电阻模块上。

热电偶模块TC:

EM231 TC支持J、K、E、N、S、T和R型热电偶,不支持B型热电偶。通过拨码设置,模块可以实现冷端补偿,但仍然需要补偿导线进行热电偶的自由端补偿。另外,该模块具有断线检测功能,未用通道应当短接,或者并联到旁边的实际接线通道上。

热电阻模块RTD:

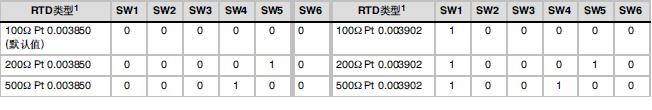

热电阻的阻值能够随着温度的变化而变化,且阻值与温度具有一定的数学关系,这种关系是电阻变化率α。RTD模块的拨码开关设置与α有关,如下图所示,就算同是 Pt100,α值不同时拨码开关的设置也不同。在选择热电阻时,请尽量弄清楚α参数,按 照对应的拨码去设置。具体请参看《S7-200可编程控制器系统手册》的附录A-热电偶和热电阻扩展模块介绍。

EM231 RTD模块具有断线检测功能,未用通道不能悬空,接法方式如下:

(1)请将一个电阻按照与已用通道相同的接线方式连接到空的通道,注意:电阻的阻值必须和RTD的标称值相同;

(2)将已经接好的那一路热电阻的所有引线,一一对应连接到空的通道上。

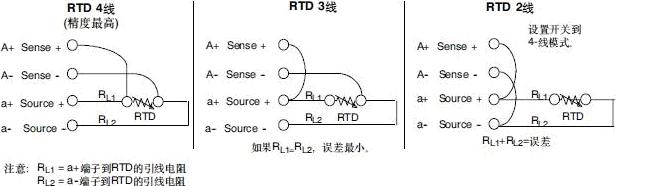

因为热电阻分2线制、3线制、4线制,所以RTD模块与热电阻的接线有3种方式,如图所示。其中,精度最高的是4线连接,精度最低的是2线连接。

提示:

(1). 在STEP7 Micor/WIN软件中(S7-200的编程软件),对于模拟量输入通道设有软件滤波功能,如图所示,具体请参见《S7-200 • LOGO• SITOP 参考》->系统块-模拟量滤波。

但是,在系统块中设置模拟量通道滤波时,RTD和TC模块占用的模拟量通道,应禁止滤波功能。

SIRIUS 3RW40 软起动器具有与 3RW30 软起动器完全相同的优点。

SIRIUS 3RW40 软起动器最突出的特点在于占用空间小。集成式旁通触点意味着电机起动后,在交易时无需考虑功率半导体(晶闸管)的功耗。从而降低了热损失,使设计更加紧凑,且无需外部旁通电路。

同时,软起动器还具有其它集成式功能,如可调限流、电机过载和本征设备保护及可选热敏电阻电机保护。由于这些功能,无需再购买和安装如过载继电器等保护设备,因此,电机额定值越高,这些功能也越重要。

内部本征设备保护可防止晶闸管热过载及功率方面的缺陷。另一个选择,可使用半导体保险丝防止晶闸管短路。

由于集成式状态监控和故障监控,该紧凑型软起动器具有许多不同的诊断功能。使用 4 个 LED 和继电器输出,来指示工作状态以及电源或相位故障、负载缺失、不允许的脱扣时间/等级设置、热过载或设备故障等,实现监控和诊断。

起动器额定功率达 250 kW(400 V 时),可用于三相电网中的标准应用。 超小外形尺寸、低功率损耗和简单起动仅仅是 SIRIUS 3RW40 软起动器的众多优点中的三个。

S0 到 S12 规格的 3RW40 软起动器适合起动带“增安”型保护 EExe 的防爆电机。

紧凑型 SIRIUS 3RW40 软起动器所需的空间仅为用于比较额定值 wye-delta 起动的接触器所需空间的三分之一。这不仅节约了控制柜和标准安装导轨的空间,还完全省去了 wye-delta 起动器所需的布线工作。这对于高电机额定值尤为明显,这些高额定值极少用作高技术解决方案。

同时,连接起动器和电机所需的电缆从六根减少到三根。紧凑的外形尺寸、短起动时间、简单布线和快速调试使得软起动器具有明显的成本优势。

这些软起动器的旁通触点在工作时由一个集成固态灭弧系统保护。 从而在故障时可防止对旁通触点的破坏,如线圈操作机构或主操作弹簧的短暂的控制电压故障、机械震动或与寿命相关的部件缺陷。

特别强大的操作机构的起动电流会在本地供电系统上施加一个不可控制的负荷。软起动器通过其电压软起动降低了该起动电流。通过可调电流限值功能,SIRIUS 3RW40 软起动器为供电系统缓解了不少压力。 一达到选择的电流限值,剩下的只需设置软起动期间的起动起点(软起动升降率由起动电压和软起动时间决定)。从此刻开始,可通过控制软起动器电压以使电机电流保持为常数。可通过电机软起动完成、本征设备保护脱扣或电机过载保护脱扣来结束该过程。该功能的结果就是电机的实际软起动时间要比软起动器上选择的软起动时间长。

由于集成有 电机过载保护功能 ,并符合标准 IEC 60947-4-2,全新软起动器无需附加过载继电器。可简单、快速地调整电机额定电流、过载脱扣时间(操作次数)设置和电机过载保护功能复位。使用 4 档旋转电位器,可在软起动器上设置不同的过载脱扣时间。 除了 10、15 和 20 级,若一个不同的电机管理控制设备用于该功能(如连接到 PROFIBUS),还可切断电机过载保护。

另外,还提供有带 晶闸管电机保护分析 功能的设备型号,额定功率 55 kW( 400 V 时)。 A 型 PTC 或 Thermoclick 测量探头都可直接连接。电机热过载以及传感器回路中的开路和短路都会造成直接断开软起动器。若软起动器曾经脱扣,与本征设备保护和电机负载保护一样,还提供有各种复位选件。通过复位按钮的手动复位,通过控制电压的短暂断开的自动或远程复位。

新设备系列采用“极性平衡”控制方法,用于保护两相控制的软起动器中的直流部件。对于两相控制软起动器,来自两个控制相位重叠的电流会流经未受控制的相位。这也是导致电机软起动中三相电流非对称分布的物理原因。这虽然不受影响,但在大多数应用中仍不可忽视。

控制功率半导体不仅导致不对称,在起动电压低于电机起动电压值的 50 % 时,还导致之前提到的直流部件产生严重的噪音。

用于这些软起动器的控制方法省去了软起动相位的直流部件,并防止了可能产生的制动扭矩。该方法创建了在速度、扭矩和电流上升上一致的电机软起动,从而可实现电机的缓和两相起动。同时,起动操作的声音质量与三相控制软起动器接近。可通过电机软起动期间不同极性半波电流的持续的动态协调和均衡来实现。因此命名为“极性平衡”。

Machine manufacturers and manufacturing plants must ensure that their machines or plants cannot cause danger due to malfunctions in addition to the general risks of electric shock, heat or radiation.

In Europe, for example, compliance with the Machinery Directive 2006/42/EC is legally stipulated by the EU work safety directive. In order to ensure compliance with this directive, it is recommended that the corresponding harmonized European standards are applied. This triggers the "assumption of conbity" and gives manufacturers and operators the legal security in terms of compliance with both national regulations and EU directives. The machine manufacturer uses the CE marking to document the compliance with all relevant directives and regulations in the free movement of goods.

Functional safety is specified in various standards. For example, EN ISO 12100 specifies standards pertaining to machine safety (risk assessment and risk reduction). IEC 61508 specifies basic requirements for electronic and programmable safety-related systems. EN 62061 (only applicable for electrical and electronic control systems) and EN ISO 13849‑1, which has replaced EN 954‑1, define the functional and safety-related requirements of safety-oriented control systems.

The above-mentioned standards define different safety requirements that the machine has to satisfy in accordance with the risk, frequency of a dangerous situation, probability of occurrence and the opportunities for recognizing impending danger.

The trend toward greater complexity and higher modularity of machines has seen a shift in safety functions away from the classical central safety functions (for example, shutdown of the complete machine using a main disconnecting means) and into the machine control system and the drives. This is often accompanied by a significant increase in productivity because the equipping times are shortened. Depending on the type of machine, it may even be possible to continue manufacturing other parts while equipping is in progress.

Integrated safety functions act much faster than those of a conventional design. The safety of a machine is increased further with Safety Integrated. Furthermore, thanks to the faster b of operation, safety measures controlled by integrated safety systems are perceived as less of a hindrance by the machine operator, therefore significantly reducing the motivation to consciously bypass safety functions.

The safety functions integrated in SINAMICS drives are described below.

SINAMICS V

SINAMICS G

SINAMICS S

V20

V90

G110

G110D

G120C

G120P/G120

G120

G110M

G120D

S110

S120

CU230P‑2

CU240B‑2

CU240E‑2

CU250S‑2

CU240M

CU240D‑2

CU250D‑2

CU305

CU310‑2

CU320‑2

Functions

–

✓

–

✓

✓

–

–

✓

✓

✓

✓

✓

✓

✓

✓

–

–

–

–

–

–

–

✓ 1)

✓

–

✓ 1)

✓

✓

✓

✓

–

–

–

–

–

–

–

–

–

–

–

–

✓ 2)

✓ 2)

✓ 2)

–

–

–

–

–

–

–

–

–

–

–

–

✓ 2)

✓ 2)

✓ 2)

–

–

–

–

–

–

–

–

✓

–

–

–

✓

✓

✓

–

–

–

–

–

–

–

–

–

–

–

–

–

✓ 2)

✓ 2)

–

–

–

–

–

–

–

✓ 1)

✓ 2)

–

✓ 1)

✓ 1)

✓ 2)

✓ 2)

✓ 2)

–

–

–

–

–

–

–

✓ 1)

✓ 2)

–

✓ 1)

✓ 1)

✓ 2)

✓ 2)

✓ 2)

–

–

–

–

–

–

–

✓ 1)

✓ 2)

–

✓ 1)

✓ 1)

✓ 2)

✓ 2)

✓ 2)

–

–

–

–

–

–

–

–

–

–

–

–

–

✓ 2)

✓ 2)

–

–

–

–

–

–

–

–

–

–

–

–

–

✓ 2)

✓ 2)

Control

–

–

–

–

✓

–

–

✓

✓

✓

✓

✓

✓

✓

✓

–

✓

–

–

✓

–

–

✓

✓

✓

✓

✓

✓

✓

✓

1) With fail-safe Control Unit.

2) With Safety Extended license.

SINAMICS drives are characterized by a large number of integrated safety functions. In combination with the sensors and safety control required for the safety functionality, they ensure that highly-effective protection for persons and machines is implemented in a practice-oriented manner.

They comply with the requirements of the following safety categories:

Note:

The Safe Brake Test (SBT) diagnostic function meets the requirements for Category 2 according to EN ISO 13849‑1.

The Safety Integrated functions are generally certified by independent institutes. You can obtain the corresponding test certificates and manufacturer's declarations from your Siemens contacts.

The integrated safety functions that are currently available are described below. Their functional safety satisfies the requirements defined in the international standard IEC 61800‑5‑2 for variable-speed drive systems.

The safety functions integrated into the SINAMICS drive system can be roughly divided into four categories:

The STO function is the most common and basic drive-integrated safety function. It ensures that no torque-generating energy can continue to affect a motor and prevents unintentional start-ups.

Activation

This function is a mechanism that prevents the drive from restarting unexpectedly, in accordance with EN 60204‑1, Section 5.4. The STO function suppresses the drive pulses (corresponds to Stop Category 0 according to EN 60204‑1). The drive is reliably torque-free. This state is monitored internally in the drive.

Application

STO has the immediate effect that the drive cannot supply any torque-generating energy. STO can be used wherever the drive will naturally reach a standstill due to load torque or friction in a sufficiently short time or when "coasting down" of the drive will not have any relevance for safety.

STO makes it possible for persons to work safely when the protective door is open (restart interlock) and is used on machines/installations with moving axes, e.g. on handling or conveyor systems.

Customer benefits

The advantage of the integrated STO safety function compared to standard safety technology using electromechanical switchgear is the elimination of separate components and the effort that would be required to wire and service them. Because of the fast electronic switching times, the function provides a shorter reb time than the conventional solution comprising electromechanical components.

The SS1 function causes a motor to stop rapidly and safely and switches the motor to torque-free mode after coming to a standstill by activating STO.

Activation

The SS1 function can safely stop the drive in accordance with EN 60204‑1, Stop Category 1. When the SS1 function is selected, the drive brakes autonomously along a quick-stop ramp and automatically activates the Safe Torque Off and Safe Brake Control functions (if configured) when the beterized safety delay time expires.

If the variant "SS1 with external stop (SS1E)" is beterized, the drive does not brake autonomously when the function is selected. In this case, the higher-level control must bring the drive to a standstill within a beterized STO transition time. The SBR (Safe Brake Ramp) and SAM (Safe Acceleration Monitor) functions are not active. SS1E is a useful function for drives that need to be stopped as a group by the Motion Control system in order to prevent potential damage to the machine or product.

Application

The SS1 function is used when, in the event of a safety-relevant incident, the drive must stop as quickly as possible with a subsequent transition into the STO state (e.g. EMERGENCY STOP). It is thus used to bring large centrifugal masses to a stop as quickly as possible for the safety of the operating personnel, or to brake motors at high speeds as quickly as possible. Examples of typical applications are saws, grinding machine spindles, centrifuges, winders and storage and retrib machines.

Customer benefits

The targeted stopping of a drive by means of SS1 reduces the risk of danger, increases the productivity of a machine, and allows the safety bances in a machine to be reduced. The principle is to bring the drive actively to a standstill, compared with just using the STO function. Complex mechanical brakes that are susceptible to wear are not normally required to brake the motor.

The SS2 function brings the motor to a standstill quickly and safely and then activates the SOS function once the motor has stopped.

Activation

The Safe Stop 2 function can safely stop the drive in accordance with EN 60204‑1, Stop Category 2. When the SS2 function is selected, the drive brakes autonomously along a quick stop ramp. In contrast to SS1, the drive control remains operational afterwards, i.e. the motor can supply the full torque required to maintain zero speed. Standstill is safely monitored (Safe Operating Stop function).

Application

As with SS1, the SS2 function ensures the quickest possible deceleration of the motor. However, the motor power is not switched off. Instead, a control system prevents it from leaving the standstill b – even if it is affected by external forces. Typical applications for SS2 include machine tools, for example.

Customer benefits

The SS2 function ensures a rapid axis stop. Because the control remains active, after the safety function is deselected, productive operation can continue without referencing. This ensures short setup and standstill times and high productivity.

With the SOS function, the stopped motor is held in b by the drive control system and its b monitored.

Activation

The SOS function constitutes safe standstill monitoring. The drive control remains in operation. The motor can therefore deliver the full torque to hold the current b. The actual b is reliably monitored. In contrast to safety functions SS1 and SS2, the speed setpoint is not influenced autonomously. After SOS has been activated, the higher-level control must bring the drive to a standstill within a beterized time and then hold the b setpoint.

Application

SOS is an ideal solution for all those applications for which the machine or parts of the machine must be at a safe standstill for certain steps, but the drive must also supply a holding torque. It is ensured that despite counter torque the drive remains in its current b. In contrast to SS1 and SS2, the drive does not brake autonomously in this case. It expects the higher-level controller to ramp down the relevant axes as a coordinated group within an adjustable delay time. This can be used to prevent any damage to the machine or product. Typical applications for SOS include winders, converting and packaging machines and machine tools.

Customer benefits

No mechanical components are necessary to keep the axis in b despite any counterforce that may occur. Due to the short switching times and the fact that the drive control always remains active, setup and downtimes are reduced. Recalibration of the axis after exiting the SOS function is not necessary. The axis can immediaby be moved again after deactivation of the SOS function.

The SBC function permits the safe control of a holding brake. SBC is always activated in parallel with STO.

Activation

A holding brake which is active in a de-energized state is controlled and monitored using safe two-channel technology. Due to the two-channel control, the brake may still be activated in the event of an insulation fault in the control cable. Errors of this kind are detected early by means of test pulses.

Note:

Safe Brake Control does not detect mechanical faults in the brake itself, such as worn brake linings. For Motor Modules, Booksize bat, the terminals for the motor brake are integrated. An additional Safe Brake Relay is required for Power Modules in blocksize bat. An additional Safe Brake Adapter is necessary for Power Modules in chassis bat.

Application

The SBC function is used in conjunction with the functions STO or SS1 to prevent the movement of an axis in the torque-free state, e.g. because of gravity.

Customer benefits

Again, the function saves the use of external hardware and the associated wiring.

The SBT diagnostic function carries out a brake function test at regular intervals or before personnel enter the danger zone.

Activation

A good way to check the proper functioning of brakes that have become worn is to apply a torque to the closed brake. Drive systems that have two brakes, e.g. motor brake and external brake, can be tested with different torque values.

Application

The SBT diagnostic function is suitable for implementing a safe brake in combination with the SBC function.

Customer benefits

The function detects faults or wear in the brake mechanics. Automatically testing the effectiveness of brakes reduces maintenance costs and increases the safety and availability of the machine or plant.

The SLS function monitors the drive to ensure that it does not exceed a preset speed or velocity limit.

Activation

The SLS function monitors the drive against a beterized speed limit. Four different limit values can be selected. As in the case of SOS, the speed setpoint is not influenced independently. After SLS has been selected, the higher-level control must bring the drive down below the selected speed limit within a beterizable time. If the speed limit is exceeded, a customizable drive-integrated fault reb occurs.

The SLS limit stage 1 can be multiplied by a factor that is transferred in 16-bit resolution via PROFIsafe. This allows an almost unlimited number of limits to be specified.

Application

The SLS function is used if people are in the danger zone of a machine and their safety can only be guaranteed by reduced speed. Typical application cases include those in which an operator must enter the danger zone of the machine for the purposes of maintenance or setting up, such as a winder in which the material is manually threaded by the operator. To prevent injury to the operator, the roller may only spin at a safely reduced speed. SLS is often also used as part of a two-stage safety concept. While a person is in a less critical zone, the SLS function is activated, and the drives are only stopped in a smaller area with higher potential risk. SLS can be used not only for operator protection, but also for machinery protection, e.g. if a maximum speed must not be exceeded.

Customer benefits

The SLS function can contribute to a significant reduction in downtime, or greatly simplify or even accelerate setup. The overall effect achieved is a higher availability of the machine. Moreover, external components such as speed monitors can be omitted.

The SSM function warns when a drive is working below an adjustable speed limit. As long as it remains below the threshold, the function issues a safety-related signal.

Activation

If a speed value drops below a beterized limit, a safety-related signal is generated. This can, for example, be processed in a safety controller to respond to the event by programming, depending on the situation.

Application

With the SSM function, in the simplest case, a safety door can be unlocked if the speed drops below a non-critical level. Another typical example is that of a centrifuge that may be filled only when it is operating below a configured speed limit.

Customer benefits

Unlike SLS, there is no drive-integrated fault reb when the speed limit is exceeded. The safe feedback can be buated in a safety control unit, allowing the user to respond appropriaby to the situation.

The SDI function ensures that the drive can only move in the selected direction.

Activation

Deviation from the direction of motion currently being monitored is detected reliably and the configured drive-integrated fault reb is initiated. It is possible to select which direction of rotation is to be monitored.

Application

The SDI function is used when the drive may only move in one direction. A typical application is to permit the operator access to a danger zone, as long as the machine is rotating in the safe direction, i.e. away from the operator. In this state, the operator can feed material into the work zone / remove material from the work zone without danger.

Customer benefits

The function saves the use of external components such as speed monitors and the associated wiring. The release of a danger zone while the machine is moving away from the operator increases productivity. Without the SDI function, the machine must be safely stopped during material loading and removal.

The SLP function monitors the axis to ensure that it remains within the permissible traversing range.

Activation

When SLP is activated, the traversing range limited by the configured software limit switches is safely monitored. If the permitted traversing range is exited, a customizable fault reb occurs. It is possible to toggle between two traversing ranges, even when the machine is in operation.

Application

SLP is used for applications in which machine operators have to enter a protection area, e.g. for feeding in and removing material. Safe monitoring of the axis b ensures that the axis cannot move into the protection area released for operators and so place them in danger, for example, on storage and retrib machines, gantry cranes or machining centers.

Customer benefits

SLP can be used for highly-effective protection area monitoring. The function does away with the use of external components such as hardware limit switches and the associated wiring expense. Due to the short reb time following a limit overshoot, safety bances can be reduced.

The SP function transfers the actual b values determined safely in the drive over safe PROFIsafe communication to a safety control.

Activation

In contrast to the SLP function that monitors the current actual b value against a limit and, in the case of an overshoot, activates a drive-integrated fault reb, SP transfers the current actual b values to the safety control. Position monitoring is implemented in the safety program of the control. Extended PROFIsafe begrams are available for transferring the b values. The b values can be transferred in 16‑bit or 32‑bit resolution, as required. A time stamp is also transferred with the b values.

Application

Tailor-made safety concepts can be created using the SP function. It is ideal for use on machines that require flexible safety functions. It is extremely versatile and can be used, for example, to implement safe, axis-specific range detection by means of safe cams. The SP function can also be used to implement multi-axis safety concepts, multi-dimensional protection areas and zone concepts.

Customer benefits

Position monitoring or speed monitoring is implemented in the safety program of the control, so the user has the flexibility for implementing tailor-made safety functions. The reb to a limit overshoot must also be specified in the safety program. This means a higher initial programming outlay, but it does offer the opportunity for initiating different fault rebs.

The Safety Integrated functions are grouped into Basic Functions and Extended Functions.

The Basic Functions are included in the standard scope of supply.

For the Extended Functions SS1 and SS2 with SAM, safe acceleration monitoring (SAM) is perbed during braking to identify any faults already during the braking phase.

With SS1 and SS2, a Safe Brake Ramp (SBR) can be configured as an alternative.

The Basic Functions – activated via on-board terminals on the device, TM54F Terminal Module or via PROFIsafe – do not require an encoder.

The safety functions for SINAMICS drives can be activated via terminals, e.g. for use of a conventional safety circuit.

For standalone safety solutions for small to medium sized applications, it is frequently sufficient that the various sensing components are directly hardwired to the drive.

For integrated safety solutions, the safety-relevant sequences are generally processed and coordinated in the fail-safe SIMATIC controller. Here, the system components communicate via the PROFINET or PROFIBUS fieldbus. The safety functions are controlled via the safe PROFIsafe communication protocol.

SINAMICS drives can be easily integrated into the plant or system topology.

SINAMICS drives support the PROFIsafe profile based on PROFINET as well as on PROFIBUS.

PROFIsafe is an open communications standard that supports standard and safety-related communication over the same communication path (wired or wireless). A second, separate bus system is therefore not necessary. The begrams that are sent are continually monitored to ensure safety-relevant communication.

Possible errors such as begrams that have been lost, repeated or received in the incorrect sequence are avoided. This is done by consecutively numbering the begrams in a safety-relevant fashion, monitoring their reception within a defined time and transferring an ID for transmitter and receiver of a begram. A CRC (cyclic redundancy check) data security mechanism is also used.

Two independent switch-off signal paths

Two independent switch-off signal paths are available. All switch-off signal paths are low active. This ensures that the system is always switched to a safe state if a component fails or in the event of cable breakage. If a fault is discovered in the switch-off signal paths, the STO or SS1 function (depending on beter settings) is activated and a system restart inhibited.

Two-channel monitoring structure

All the main hardware and software functions for Safety Integrated are implemented in two independent monitoring channels (e.g. switch-off signal paths, data management, data comparison). A cyclic crosswise comparison of the safety-relevant data in the two monitoring channels is carried out.

The monitoring functions in each monitoring channel work on the principle that a defined state must prevail before each b is carried out and a specific acknowledgement must be made after each b. If these expectations of a monitoring channel are not fulfilled, the drive coasts to a standstill (two channel) and an appropriate message is output.

Forced dormant error detection using test stop

The functions and switch-off signal paths must be tested at least once within a defined time in order to meet requirements as per EN ISO 13849‑1 and IEC 61508 in terms of timely fault detection. This must be implemented either in cyclic manual mode or the test stop must be automatically initiated as part of the process. The test stop cycle is monitored, and after a specific time has been exceeded, an alarm is output. A test stop does not require a POWER ON. The acknowledgment is set by canceling the test stop request.

Examples of when forced dormant error detection must be perbed:

Incremental encoders or absolute encoders can be used for safe sensing of the b values on a drive.

Safe actual value sensing relies on redundant buation of the incremental tracks A/B that supply sin/cos signals of 1 Vpp. Only encoders of the type whose A/B track signals are created and processed using purely analog techniques can be used.

HTL/TTL incremental encoders may also be used. In this case, safe actual value sensing is achieved by using two independent encoders. The minimum possible speed resolution must also be taken into account.

The encoder signals are b via Sensor Modules.

As an alternative, motors with an integrated DRIVE‑CLiQ interface can be used. The speed or b actual values are generated directly in the motor as safe values and are transferred to the Control Unit over safe communication via DRIVE‑CLiQ.

Certified built-on rotary encoders with DRIVE-CLiQ interface may also be used (see

The encoder must be mechanically attached in such a manner that the encoder shaft is unable to unplug or slide off. For notes on this, see IEC 61800‑5‑2: 2016, Table D.16.

A list of Siemens motors that fulfill the electrical and mechanical requirements is available at:

The following can be used for safe speed/b sensing:

Single-encoder system

Example: Single-encoder system

In a single-encoder system, the motor encoder is used exclusively for safe actual value sensing.

Dual-encoder system

Example: Dual-encoder system

In the case of the 2-encoder system, the safe actual values for a drive are provided by two separate encoders. The actual values are transferred to the Control Unit over DRIVE-CLiQ. When motors without a DRIVE-CLiQ connection are used, a Sensor Module must be provided.

HTL/TTL incremental encoders can be used as an alternative with a dual-encoder system. Either two HTL/TTL encoders, one dual-HTL/TTL encoder or one HTL/TTL encoder and one sin/cos encoder can be used.

The safety functions are listed below with criteria for actual value sensing

Functions

Abbreviation

With encoder

Without encoder

Debion

Basic Functions

Safe Torque Off

STO

Yes

Yes

Safe Torque Off

Safe Stop 1

SS1

Yes

Yes

Safe stopping process in accordance with stop category 1

Safe Brake Control

SBC

Yes

Yes

Safe Brake Control

Extended Functions

Safe Torque Off

STO

Yes

Yes

Safe Torque Off

Safe Stop 1

SS1

Yes

Yes 1)

Safe stopping process in accordance with stop category 1

Safe Brake Control

SBC

Yes

Yes

Safe Brake Control

Safe Operating Stop

SOS

Yes

No

Safe monitoring of the standstill b

Safe Stop 2

SS2

Yes

No

Safe stopping process in accordance with stop category 2

Safely Limited Speed

SLS

Yes

Yes 1)

Safe monitoring of the maximum speed

Safe Speed Monitor

SSM

Yes

Yes 1)

Safe monitoring of the minimum speed

Safe Direction

SDI

Yes

Yes 1)

Safe monitoring of the direction of motion

Safely Limited Position

SLP

Yes

No

Safely-limited b

Safe Position

SP

Yes

Yes 2)

Safe transfer of b values

Safe Brake Test

SBT

Yes

No

Diagnostic function for safe testing of the required holding torque of a brake

1) The use of this safety function without encoder is permitted for induction motors or synchronous motors of the SIEMOSYN series.

2) Only for the transmission of relative b values. An encoder is required to transmit absolute b values.

The Safety Integrated Function Manual contains detailed inbation about the safety functions.

Further manuals pertaining to Safety Integrated in drive systems can be found on the Internet at

Further inbation about Safety Integrated in SINAMICS can be found on the Internet at

Further inbation about Safety Integrated in SIMOTION can be found on the Internet at

联 系 人:张柏(销售经理)

工作QQ:254598303

联系人 :13817011145 wei信同步

邮箱( Email )::254598303@qq.com

业务范围:

列表价格

显示价格

客户价格

显示价格

PDF 格式的数据表

下载

服务和支持 (手册,认证,问答...)

下载

产品

商品编号(市售编号)

3RW4465-2BC46

产品说明

SIRIUS 软起动器-电压为690V、温度40度时的标准接线值为:1,076A、1100KW;内三角电路值高达600V,交流400-460 V、交流230V,弹簧接线端子

产品家族

3RW44 软启动器

产品生命周期 (PLM)

PM300:有效产品

价格数据

价格组 / 总部价格组

XJ / 42H

列表价格

显示价格

客户价格

显示价格

金属系数

LAO----

交付信息

出口管制规定

AL : N / ECCN : N

工厂生产时间

25 天

净重 (Kg)

96.85 Kg

产品尺寸 (W x L X H)

未提供

包装尺寸

645.00 x 835.00 x 480.00

包装尺寸单位的测量

MM

数量单位

1 件

包装数量

1

其他产品信息

EAN

4011209681101

UPC

未提供

商品代码

85371099

LKZ_FDB/ CatalogID

CC-IC10

产品组

3728

原产国

德国

Compliance with the substance restrictions according to RoHS directive

RoHS 合规开始日期: 2012.05.01

产品类别

C: 产品制造/生产到订单,无法重复使用或再利用,也不能通过信用退货。

电气和电子设备使用后的收回义务类别

没有电气和电子设备使用后回收的义务

分类

版本

分类

eClass

5.1

27-02-41-01

eClass

6

27-37-09-07

eClass

7.1

27-37-09-07

eClass

8

27-37-09-07

eClass

9

27-37-09-07

eClass

9.1

27-37-09-07

ETIM

4

EC000640

ETIM

5

EC000640

ETIM

6

EC000640

IDEA

4

4740

西门子6ES72320HB220A8

西门子6ES72320HB220A8

“增安型”防护 EEx e,符合 ATEX 指令 94/9/EC

功能

15KW/29A

3RW4422-3BC44

18.5KW/36A

3RW4423-3BC44

22KW/47A

3RW4424-3BC44

30KW/57A

3RW4425-3BC44

37KW/77A

3RW4426-3BC44

45KW/93A

3RW4427-3BC44

55KW/113A

3RW4434-6BC44

75KW/134A

3RW4435-6BC44

90KW/162A

3RW4436-6BC44

110KW/203A

3RW4443-6BC44

132KW/250A

3RW4444-6BC44

160KW/313A

3RW4445-6BC44

200KW/356A

3RW4446-6BC44

250KW/432A

3RW4447-6BC44

315KW/551A

3RW4453-6BC44

355KW/590A

3RW4454-6BC44

400KW/693A

3RW4455-6BC44

450KW/780A

3RW4456-6BC44

500KW/880A

3RW4457-6BC44

560KW/970A

3RW4458-6BC44

630KW/1076A

3RW4465-6BC44

710KW/1214A

3RW4466-6BC44

跳转到

Overview

Legal framework

Safety-related standards

Trend toward integrated safety systems

![]()

Functions

Safety functions integral to the SINAMICS drives

Functions for safely stopping a drive

Functions for safe brake management

Functions for safely monitoring the motion of a drive

Functions for safely monitoring the b of a drive

Safe Torque Off (STO)

Safe Stop 1 (SS1)

Safe Stop 2 (SS2)

Safe Operating Stop (SOS)

Safe Brake Control (SBC)

Safe Brake Test (SBT)

Safely-Limited Speed (SLS)

Safe Speed Monitor (SSM)

Safe Direction (SDI)

Safely Limited Position (SLP)

Safe Position (SP)

Basic Functions and Extended Functions

The Extended Functions must be activated by a license.

Activation of the integrated safety functions

PROFIsafe

The operating principle of Safety Integrated

Safe speed/b sensing

https://support.industry.siemens.com/cs/document/65402168).

https://support.industry.siemens.com/cs/document/33512621

![]()

More inbation

https://support.industry.siemens.com/cs/document/99668646

https://support.industry.siemens.com/cs/ww/en/ps/13231/man

http://www.siemens.com/safety-drives

http://www.siemens.com/simotion-d-safety-integrated