LB-52NSU日本神钢焊条 低合金低温钢高强钢焊条进口焊条进口焊丝

西安骏焊专业销售日本神钢焊条焊丝

When pipe root pass welding must be conducted from outside rather than inside in order to b the back bead inside the pipe, GTAW or SMAW are generally favored. Kobe Steel has long marketed FAMILIARC™ LB-52U as well as FAMILIARC™ LB-62U for this purpose, and they still serve as Kobe’s most reliable, “one and only” products worldwide.

In addition to meeting the always-changing and diverse specifications of pipelines, TRUSTARC™ LB-52NSU has been developed specifically for root pass welding of pipes for low temperature service. It is a covered, low hydrogen type electrode equivalent to AWS A5.5 E7016-G. It offers superb notch toughness at -60°C and very low diffusible hydrogen content of about 3.0ml/100g. The chemistries, mechanical properties of all weld bl and diffusible hydrogen content of TRUSTARC™ LB-52NSU are shown in Tables 3, 4 and 5 respectively.

Table 1: Covered electrodes for girth welding|

API 5L pipe grade |

Welding pass |

Low hydrogen type |

High cellulose type |

|

|---|---|---|---|---|

|

Vertical upward b |

Vertical downward b |

|||

| X42-X52 | Root |

LB-52U LB-52NSU |

LB-78VS | KOBE-6010 |

| Hot |

LB-52-18 LB-52NS |

|||

| Filler & Cap | ||||

| X56-X60 | Root |

LB-52U LB-52NSU |

KOBE-6010 KOBE-7010S |

|

| Hot |

LB-52-18 LB-52NS |

KOBE-7010S | ||

| Filler & Cap | ||||

| X65 | Root | LB-52U | LB-88VS |

KOBE-7010S KOBE-8010S |

| Hot |

LB-62 LB-62D |

|||

| Filler & Cap | KOBE-8010S | |||

| X70 | Root | LB-62U |

KOBE-7010S KOBE-8010S |

|

| Hot |

LB-62 LB-62D |

|||

| Filler & Cap | KOBE-8010S | |||

| X80 | Root | LB-62U |

LB-98VS LB-108VS |

—— |

| Hot |

LB-65D LB-106 |

|||

| Filler & Cap | ||||

| X100 | Root | —— | LB-118VS | —— |

| Hot |

LB-80L LB-116 |

|||

| Filler & Cap | ||||

|

API 5L pipe grade |

Welding pass |

Temperature (°C) | ||

|---|---|---|---|---|

| -20 | -40 | -60 | ||

| X42-X56 | Root & Hot |

TG-S50 MX-100T |

TG-S1N MX-A55T |

|

| Filler & Cap |

DW-A50 DW-A50SR |

DW-A55E DW-A55ESR |

DW-A55L DW-A55LSR DW-A81Ni1 |

|

| X60 | Root & Hot | TG-S62 | TG-S60A | |

| Filler & Cap |

DW-A55E DW-A55ESR |

DW-A55L DW-A55LSR DW-A81Ni1 |

||

| X65 | Root & Hot | TG-S62 | TG-S60A | |

| Filler & Cap |

DW-A55E DW-A55ESR |

DW-A55L DW-A55LSR DW-A81Ni1 |

||

| X70 | Root & Hot | TG-S62 | TG-S60A | |

| Filler & Cap | DW-A70L |

DW-A55L DW-A81Ni1 |

||

| X80 | Root & Hot | TG-S80AM | ||

| Filler & Cap | DW-A70L | —— | ||

| X100 | Root & Hot | TG-S80AM | ||

| Filler & Cap | DW-A80L | —— | —— | |

| C | Si | Mn | P | S | Ni | Ti | B |

|---|---|---|---|---|---|---|---|

| 0.06 | 0.62 | 1.25 | 0.016 | 0.004 | 0.50 | 0.014 | 0.0027 |

| Tensile properties | Notch toughness | ||||||

|---|---|---|---|---|---|---|---|

|

0.2% PS (MPa) |

TS (MPa) |

EI (%) |

RA (%) |

Absorbed energy:J (Brittle fracture: %) |

FATT (°C) |

||

| -80°C | -60°C | -40°C | |||||

| 511 | 598 | 32 | 78 |

43(60) 55(60) 41(60) Av.46(60) |

44(55) 72(55) 58(52) Av.58(54) |

70(50) 137(35) 144(35) Av.117(40) |

-53 |

| Electrode dia (mm) | 1 | 2 | 3 | 4 | Ave. |

|---|---|---|---|---|---|

| 3.2 | 2.8 | 3.3 | 3.5 | 3.0 | 3.2 |

Note: Tested b: According to AWS A4.3.(Gas chromatography)

Welding current: 120 A (DCEP)

Welding atmosphere: 21°C x RH10%

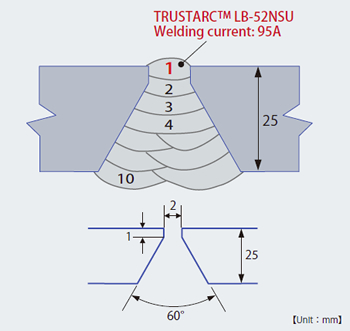

Figure 3: Groove shape and pass sequence of butt joint

welding with TRUSTARCTM LB-52NSU(root pass only)

and TRUSTARCTM LB-52NS

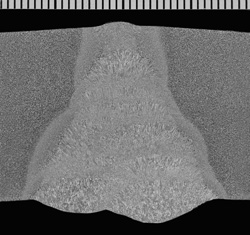

In welding a butt joint on a 25 mm thick plate, 3.2 mm dia. TRUSTARC™ LB-52NSU was used for the root pass with DC 95 amp, and 3.2 mm dia. TRUSTARC™ LB-52NS was used for the second pass onwards with DC 110 amp in the vertical upward b. The preheating and interpass temperatures were kept between 115 and 135°C. Figure 3 shows the groove shape and the pass sequence and Figure 4, the macrostructure of the weld bl. The chemistries and the tensile properties are shown in Tables 6 and 7, respectively and the notch toughness properties and the transition curve of the butt joint weld bl are shown in Table 8 and Figure 5, respectively. (Note: both TRUSTARC™ LB-52NSU and TRUSTARC™ LB-52NS are specified as AWS A5.5 E7016-G).

Figure 4: Macrostructure of butt joint weld

bl

| Location | C | Si | Mn | P | S | Ni | Ti | B |

|---|---|---|---|---|---|---|---|---|

| Face | 0.07 | 0.31 | 1.40 | 0.008 | 0.003 | 0.50 | 0.013 | 0.0022 |

| Reverse | 0.08 | 0.30 | 1.36 | 0.009 | 0.003 | 0.43 | 0.014 | 0.0023 |

| Location | Tensile properties | |||

|---|---|---|---|---|

| Center |

0.2%PS (MPa) |

TS (MPa) |

El (%) |

RA (%) |

| 506 | 577 | 25 |

81 |

|