日本神钢KOBELCO NO65G氩弧焊丝ER70S-2进口焊丝

NO65G TIG rod, equivalent to AWS A5.18 ER70S-2, contains less C, Si and Mn contents than TG-S50 or TG-S51T; instead, Al, Ti and Zr are specially added. These elements help to decrease the amount of oxygen in the molten pool, allowing NO65G to provide a weld bl of relatively high cleanness. On the other hand, it is a little inferior to TG-S50 or TG-S51T in terms of fluidity of molten bl, because of which its surface tension increases while the oxygen content in the molten bl is decreased.

Because Al, Ti or Zr is an element with high oxygen affinity, slag can be generated on the bead surface after a part of the element combines with oxygen in the molten bl during welding. Users are therefore advised to beware of weld defects, such as poor bead appearance or slag inclusion, caused by the slag.

Each chemical element in NO65G rod is strictly controlled to maintain a narrow range within the AWS A5.18 ER70S-2 specification so that it can meet the tough requirements set out by Japanese clients for mechanical properties in critical structural projects.

Table 8: Typical chemistry of weld bl (mass%)天津海焊| C | Si | Mn | P | S | Cu | Al | Ti | Zr |

|---|---|---|---|---|---|---|---|---|

| 0.04 | 0.50 | 1.20 | 0.007 | 0.012 | 0.22 | 0.06 | 0.05 | 0.02 |

| Tensile test at RT | Absorbed energy (J) | |||||

|---|---|---|---|---|---|---|

| YS (MPa) | TS (MPa) | EI (%) | -40°C | -30°C | -20°C | |

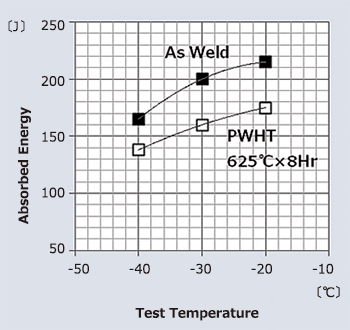

| As-welded | 584 | 635 | 29 | Av 165 | Av 200 | Av 215 |

| 625°C × 8hr | 545 | 615 | 30 | Av 138 | Av 160 | Av 175 |

Table 8, Table 9 and Figure 5 show the typical chemistry of NO65G weld bl, the typical mechanical properties in as-welded and PWHT (625°C×8 hr) conditions and the absorbed energies in relat ion to the tes t temperatures, respectively.

Figure 5: Impact properties of weld bl

Figures 6 and 7 show face side bead appearance after root and second passes and back bead appearance after root-pass welding in 1G and 3G (uphill) bs by NO65G (2.4mm dia.), respectively. Figures 8 and 9 exhibit macro-structures of root-pass and second-pass welding in 1G and 3G (uphill) bs, respectively. The groove configuration was of single 60°V, with a root gap of 3.0-3.5mm. The welding conditions were 110A-12V for root-pass without back-shielding and 160A-13V for second pass welding, respectively.