长沙奈欧自动化设备有限公司专业销售西门子S7-200 / 300/400 / 1200PLC,数控系统,变频器,人机界面,触摸屏,伺服,电机,西门子电缆等,并可提供西门子维修服务,欢迎来电垂询

联系人: 刘文秀(销售经理)

24小时热线;137 6211 0473

QQ:1533714462

地址:长沙市岳麓区天顶街道尖山安置公寓楼702室

西门子6AG1677-2AA31-4EB0西门子 CPU 西门子6AG1677-2AA31-4EB0西门子 CPU 西门子6AG1677-2AA31-4EB0西门子 CPU

SIPLUS extreme products are based on SIMATIC standard products. The contents listed here were taken from the respective standard products. SIPLUS extreme specific inbation was added.

The ET 200SP Open Controller CPU 1515SP PC is a rugged, compact control system that combines the functionality of an ET 200SP controller with a PC-based platb. The CPU offers the entire value added of the ET 200SP system, the S7-1500 controller family and the TIA world combined. The controller can be used to control special and series machines, or to control plants in a distributed configuration. The standard user program is generated in the TIA Portal. The controller is especially suitable for machines with high data volumes, e.g. for quality assurance with camera inspection and image transmission, or printer connection. The CPU 1515SP PC develops its full potential particularly when special automation functions are to be integrated using the programming languages C or C++, when a close connection of Windows software to the software controller is required, or when large volumes of data have to be stored.

The CPU 1515SP PC + HMI with pre-installed WinCC Runtime Advanced is offered for additional HMI functionality. This enables control and visualization to be integrated on a single device.

The CPU 1515SP PC is snapped directly onto the DIN rail like other ET 200SP CPUs. ET 200SP I/O modules can be plugged in directly and centrally, and they communicate via the integrated backplane bus. PN IO and S7 communication can be established and distributed I/Os can be connected via the PROFINET adapter of the ET 200SP system. This way, the system can be integrated into existing automation environments with little effort.

The PROFIBUS CM DP module adds PROFIBUS communication to the CPU 1515SP PC.

The following interfaces are available:

The CPU also possesses the following:

Different turnkey and pre-configured variants are available for various requirements:

Article number

6AG1677-2AA31-4EB0

6AG1677-2AA40-4AA0

SIPLUS ET 200SP CPU 1515SP PC 4GB

SIPLUS ET 200SP CPU 1515SP PC SPARE 4GB

General inbation

Product type designation

CPU 1515SP PC

CPU 1515SP PC

HW functional status

FS05

FS03

Firmware version

V2.0

Installed software

● Visualization

No

No

● Control

S7-1500 Software Controller CPU 1505SP V2.0

No

Configuration control

via dataset

Yes

Control elements

Mode selector switch

1

1

Supply voltage

Type of supply voltage

24 V DC

24 V DC

permissible range, lower limit (DC)

19.2 V

19.2 V

permissible range, upper limit (DC)

28.8 V

28.8 V

Reverse polarity protection

Yes

Yes

Mains buffering

● Mains/voltage failure stored energy time

5 ms

5 ms

Input current

Current consumption (rated value)

1.5 A; Full processor load, incl. ET 200SP modules and using USB

1.5 A; Full processor load, incl. ET 200SP modules and using USB

Current consumption (in no-load operation), typ.

0.6 A

0.6 A

Inrush current, max.

4.7 A; Rated value

4.7 A; Rated value

Power

Active power b, max.

36 W; incl. ET 200SP modules and using USB

36 W; incl. ET 200SP modules and using USB

Infeed power to the backplane bus

8.75 W

8.75 W

Power loss

Power loss, typ.

15 W; without ET 200SP modules and without using USB

15 W; without ET 200SP modules and without using USB

Processor

Processor type

Dual-Core 1 GHz, AMD G Series APU T40E

Dual-Core 1 GHz, AMD G Series APU T40E

Memory

Type of memory

DDR3-SDRAM

DDR3-SDRAM

Main memory

4 GB RAM

4 GB RAM

CFast memory card

Yes; 8 GB flash memory

No

SIMATIC memory card required

No

Flash Disk

8 GB

Work memory

● integrated (for program)

1 Mbyte

● integrated (for data)

5 Mbyte

● integrated (for CPU function library of CPU Runtime)

10 Mbyte

Load memory

● integrated (on PC mass storage)

320 Mbyte

Backup

● with UPS

Yes; all memory areas declared retentive

● with non-volatile memory

Yes

CPU processing times

for bit operations, typ.

10 ns

for word operations, typ.

12 ns

for fixed point arithmetic, typ.

16 ns

for floating point arithmetic, typ.

64 ns

CPU-blocks

Number of elements (total)

6 000; In addition to blocks such as DBs, FBs and FCs, UDTs, b constants, etc. are also regarded as elements

DB

● Number, max.

5 999; Number range: 1 to 65535

● Size, max.

5 Mbyte

FB

● Number, max.

5 998; Number range: 1 to 65535

● Size, max.

512 kbyte

FC

● Number, max.

5 999; Number range: 1 to 65535

● Size, max.

512 kbyte

OB

● Size, max.

1 048 kbyte

● Number of free cycle OBs

100

● Number of time alarm OBs

20

● Number of delay alarm OBs

20

● Number of cyclic interrupt OBs

20

● Number of process alarm OBs

50

● Number of DPV1 alarm OBs

3

● Number of isochronous mode OBs

1

● Number of technology synchronous alarm OBs

2

● Number of startup OBs

100

● Number of asynchronous error OBs

4

● Number of synchronous error OBs

2

● Number of diagnostic alarm OBs

1

Nesting depth

● per priority class

24

Counters, timers and their retentivity

S7 counter

● Number

2 048

Retentivity

— adjustable

Yes

IEC counter

● Number

Any (only limited by the main memory)

Retentivity

— adjustable

Yes

S7 times

● Number

2 048

Retentivity

— adjustable

Yes

IEC timer

● Number

Any (only limited by the main memory)

Retentivity

— adjustable

Yes

Data areas and their retentivity

Retentive data area (incl. timers, counters, flags), max.

410 kbyte; For storage in NVRAM; for storage in mass storage 5 242 020 bytes

Flag

● Number, max.

16 kbyte

● Number of clock memories

8; 8 clock memory bits, grouped into one clock memory byte

Data blocks

● Retentivity adjustable

Yes

● Retentivity preset

No

Local data

● per priority class, max.

64 kbyte; max. 16 KB per block

Address area

Number of IO modules

8 192

I/O address area

● Inputs

32 kbyte; All bs are in the process image

● Outputs

32 kbyte; All outputs are in the process image

of which per assigned PC interface

— Inputs (volume)

8 kbyte

— Outputs (volume)

8 kbyte

Subprocess images

● Number of subprocess images, max.

32

Hardware configuration

Integrated power supply

Yes

Yes

Number of distributed IO systems

20

Number of DP masters

● Via CM

1

Rack

● Modules per rack, max.

64; CPU 1515SP PC + 64 modules + server module

64; CPU + 64 modules + server module (mounting b max. 1 m)

● Number of lines, max.

1

1

PtP CM

● Number of PtP CMs

the number of connectable PtP CMs is only limited by the number of available slots

Time of day

Clock

● Type

Hardware clock

Hardware clock

● Hardware clock (real-time)

Yes; Resolution: 1 s

Yes; Resolution: 1 s

● Backup time

6 wk; At 40 °C ambient temperature, typically

6 wk; At 40 °C ambient temperature, typically

● Deviation per day, max.

10 s; Typ.: 2 s

10 s; Typ.: 2 s

Clock synchronization

● supported

Yes

● to DP, master

No

● on Ethernet via NTP

Yes

● on Windows clock, slave

Yes

Interfaces

Number of industrial Ethernet interfaces

2

1

Number of PROFINET interfaces

1

1

Number of PROFIBUS interfaces

1

Number of RS 485 interfaces

1; Via CM DP module

Number of USB interfaces

3; 3x USB 2.0 on the front, 500 mA each – of which 2x 500 mA and 1x 100 mA simultaneously

3; 3x USB 2.0 on the front, 500 mA each – of which 2x 500 mA and 1x 100 mA simultaneously

Number of SD card slots

1

1

Video interfaces

● Graphics interface

1x DVI-I

1x DVI-I

1. Interface

Interface type

PROFINET

PROFINET

automatic detection of transmission rate

Yes

Yes

Autonegotiation

Yes

Yes

Autocrossing

Yes

Yes

Interface types

● Number of ports

2

2

● integrated switch

Yes

Yes

● RJ 45 (Ethernet)

Yes; Via BusAdapter BA 2x RJ45

Yes; Via BusAdapter BA 2x RJ45

— Transmission rate, max.

100 Mbit/s

100 Mbit/s

— Industrial Ethernet status LED

Yes

Yes

● BusAdapter (PROFINET)

Yes; Applicable BusAdapter: BA 2x RJ45, BA 2x FC

Functionality

● Number of connections via this interface

88

● PROFINET IO Controller

Yes

● PROFINET IO Device

Yes

● SIMATIC communication

Yes

● Open IE communication

Yes

● Web server

Yes

PROFINET IO Controller

Services

— Isochronous mode

Yes

— shortest clock pulse

500 µs

— IRT

Yes

— MRP

Yes

— MRPD

Yes

— Prioritized startup

Yes; Max. 32 PROFINET devices

— Number of connectable IO Devices, max.

128

— Of which IO devices with IRT, max.

64

— of which in line, max.

64

— Number of connectable IO Devices for RT, max.

128

— of which in line, max.

128

— Number of IO Devices that can be simultaneously activated/deactivated, max.

8

— IO Devices changing during operation (partner ports), supported

Yes

— Number of IO Devices per tool, max.

8

— Updating times

The minimum value of the update time also depends on communication share set for PROFINET IO, on the number of IO devices, and on the quantity of configured user data

Update time for IRT

— for send cycle of 500 µs

500 µs to 8 ms

— for send cycle of 1 ms

1 ms to 16 ms

— for send cycle of 2 ms

2 ms to 32 ms

— for send cycle of 4 ms

4 ms to 64 ms

— With IRT and beterization of "odd" send cycles

Update time = set "odd" send clock (any multiple of 125 µs: 375 µs, 625 µs ... 3 875 µs)

Update time for RT

— for send cycle of 500 µs

500 µs to 256 ms

— for send cycle of 1 ms

1 ms to 512 ms

— for send cycle of 2 ms

2 ms to 512 ms

— for send cycle of 4 ms

4 ms to 512 ms

PROFINET IO Device

Services

— Isochronous mode

No

— IRT

Yes

— MRP

Yes

— MRPD

Yes

— Prioritized startup

Yes

— Shared device

Yes

— Number of IO Controllers with shared device, max.

4

2. Interface

Interface type

Integrated Ethernet interface

Integrated Ethernet interface

Physics

RJ45

automatic detection of transmission rate

Yes

Yes

Autonegotiation

Yes

Yes

Autocrossing

Yes

Yes

Interface types

● Number of ports

1

1

● RJ 45 (Ethernet)

Yes; Integrated

Yes; Integrated

— Transmission rate, max.

1 000 Mbit/s

1 000 Mbit/s

— Industrial Ethernet status LED

No

No

3. Interface

Interface type

PROFIBUS with CM DP

Interface types

● RS 485

Yes

Functionality

● Number of connections via this interface

44

● PROFIBUS DP master

Yes

● PROFIBUS DP slave

Yes

● SIMATIC communication

Yes

DP master

● Number of DP slaves, max.

125

Services

— Equidistance

No

— Isochronous mode

No

DP slave

Services

— Equidistance

No

— Isochronous mode

No

RS 485

● Transmission rate, max.

12 Mbit/s

12 Mbit/s

Protocols

Number of connections

● Number of connections, max.

88

● Number of connections reserved for ES/HMI/web

10

● Number of S7 routing paths

16

SIMATIC communication

● PG/OP communication

Yes

● S7 routing

Yes

● S7 communication, as server

Yes

● S7 communication, as client

Yes

● User data per job, max.

64 kbyte

Open IE communication

● TCP/IP

Yes

— Data length, max.

64 kbyte

● ISO-on-TCP (RFC1006)

Yes

— Data length, max.

64 kbyte

● UDP

Yes

— Data length, max.

1 472 kbyte

● SNMP

Yes

● DCP

Yes

● LLDP

Yes

Web server

● HTTP

Yes; Via Windows and PROFINET interface

● HTTPS

Yes; Only via PROFINET interface

OPC UA

● OPC UA Server

Data access (read, write, subscribe), runtime license required

— Application authentication

Available security policies: None, Basic128Rsa15, Basic256Rsa15, Basic256Sha256

— Security policies

Available security policies: None, Basic128Rsa15, Basic256Rsa15, Basic256Sha256

— User authentication

"anonymous" or by user name & password

Further protocols

● MODBUS

Yes; MODBUS TCP

Media redundancy

● Switchover time on line break, typ.

200 ms

● Number of stations in the ring, max.

50

S7 message functions

Number of login stations for message functions, max.

32

Program alarms

Yes

Number of configurable program alarms

10 000

Number of simultaneously active program alarms

● Number of program alarms

1 000

● Number of alarms for system diagnostics

200

● Number of alarms for motion technology bs

160

Test commissioning functions

Joint commission (Team Engineering)

Yes; Parallel online access possible for up to 8 engineering systems

Status block

Yes; up to 8 simultaneously

Single step

No

Status/control

● Status/control variable

Yes

● Variables

Inputs, outputs, memory bits, DB, times, counters

● Number of variables, max.

— of which status variables, max.

200

— of which control variables, max.

200

Forcing

● Forcing

Yes

● Forcing, variables

Inputs, outputs

● Number of variables, max.

200

Diagnostic buffer

● present

Yes

● Number of entries, max.

1 000

— of which powerfail-proof

300

Traces

● Number of configurable Traces

4

● Memory size per trace, max.

512 kbyte

Interrupts/diagnostics/status inbation

Diagnostics indication LED

● RUN/STOP LED

Yes

● ERROR LED

Yes

● MAINT LED

Yes

Supported technology bs

Motion Control

Yes

● Number of available Motion Control resources for technology bs (except cam disks)

2 400

● Required Motion Control resources

— per speed-controlled axis

40; per axis

— per bing axis

80; per axis

— per synchronous axis

160; per axis

— per external encoder

80; per external encoder

— per output cam

20; per cam

— per cam track

160; per cam track

— per probe

40; per probe

● Positioning axis

— Number of bing axes at motion control cycle of 4 ms (typical value)

5

— Number of bing axes at motion control cycle of 8 ms (typical value)

12

Controller

● PID_Compact

Yes; Universal PID controller with integrated optimization

● PID_3Step

Yes; PID controller with integrated optimization for valves

● PID-Temp

Yes; PID controller with integrated optimization for temperature

Counting and measuring

● High-speed counter

Yes

EMC

Emission of radio interference acc. to EN 55 011

● Limit class A, for use in industrial areas

Yes

Yes

Standards, approvals, certificates

CE mark

Yes

Yes

Ambient conditions

Ambient temperature during operation

● min.

0 °C

0 °C

● max.

60 °C; Up to 60 °C with max. 32 ET 200SP modules and 3x 100 mA USB load; up to 55 °C with max. 64 ET 200SP modules and 2x max. 500 mA and 1x max. 100 mA USB load

60 °C; Up to 60 °C with max. 32 ET 200SP modules and 3x 100 mA USB load; up to 55 °C with max. 64 ET 200SP modules and 2x max. 500 mA and 1x max. 100 mA USB load

● horizontal installation, min.

0 °C; = Tmin

0 °C; = Tmin

● horizontal installation, max.

60 °C; = Tmax; up to 60 °C with max. 32 ET 200SP modules and 3x 100 mA USB load; up to 55 °C with max. 64 ET 200SP modules and 2x max. 500 mA and 1x max. 100 mA USB load

60 °C; = Tmax; up to 60 °C with max. 32 ET 200SP modules and 3x 100 mA USB load; up to 55 °C with max. 64 ET 200SP modules and 2x max. 500 mA and 1x max. 100 mA USB load

● vertical installation, min.

0 °C; = Tmin

0 °C; = Tmin

● vertical installation, max.

50 °C; = Tmax; at max. 32 ET 200SP modules and 3x 100 mA USB load

50 °C; = Tmax; at max. 32 ET 200SP modules and 3x 100 mA USB load

Ambient temperature during storage/transportation

● min.

-40 °C

-40 °C

● max.

70 °C

70 °C

Altitude during operation relating to sea level

● Installation altitude above sea level, max.

5 000 m

5 000 m

● Ambient air temperature-barometric pressure-altitude

Tmin ... Tmax at 1 140 hPa ... 795 hPa (-1 000 m ... +2 000 m) // Tmin ... (Tmax - 10 K) at 795 hPa ... 658 hPa (+2 000 m ... +3 500 m) // Tmin ... (Tmax -20 K) at 658 hPa ... 540 hPa (+3 500 m ... +5 000 m)

Tmin ... Tmax at 1 140 hPa ... 795 hPa (-1 000 m ... +2 000 m) // Tmin ... (Tmax - 10 K) at 795 hPa ... 658 hPa (+2 000 m ... +3 500 m) // Tmin ... (Tmax -20 K) at 658 hPa ... 540 hPa (+3 500 m ... +5 000 m)

Relative humidity

● With condensation, tested in accordance with IEC 60068-2-38, max.

100 %; RH incl. condensation / frost (no commissioning in bedewed state), horizontal installation

100 %; RH incl. condensation / frost (no commissioning in bedewed state), horizontal installation

Vibrations

● Operation, tested according to IEC 60068-2-6

Yes

Yes

● Transport, tested acc. to IEC 60068-2-6

Yes

Yes

Shock testing

● tested according to IEC 60068-2-6

Yes

Yes

● tested according to IEC 60068-2-27

Yes

Yes

● tested according to IEC 60068-2-29

Yes

Yes

● Storage/transport, tested acc. to IEC 60068-2-27

Yes

Yes

Resistance

Coolants and lubricants

— Resistant to commercially available coolants and lubricants

Yes

Yes

Use in stationary industrial systems

— to biologically active substances according to EN 60721-3-3

Yes; Class 3B2 mold, fungus and dry rot spores (with the exception of fauna); Class 3B3 on request

Yes; Class 3B2 mold, fungus and dry rot spores (with the exception of fauna); Class 3B3 on request

— to chemically active substances according to EN 60721-3-3

Yes; Class 3C4 (RH < 75 %) incl. salt spray acc. to EN 60068-2-52 (severity degree 3); *

Yes; Class 3C4 (RH < 75 %) incl. salt spray acc. to EN 60068-2-52 (severity degree 3); *

— to mechanically active substances according to EN 60721-3-3

Yes; Class 3S4 incl. sand, dust, *

Yes; Class 3S4 incl. sand, dust, *

Use on ships/at sea

— to biologically active substances according to EN 60721-3-6

Yes; Class 6B2 mold and fungal spores (excluding fauna); Class 6B3 on request

Yes; Class 6B2 mold and fungal spores (excluding fauna); Class 6B3 on request

— to chemically active substances according to EN 60721-3-6

Yes; Class 6C3 (RH < 75 %) incl. salt spray acc. to EN 60068-2-52 (severity degree 3); *

Yes; Class 6C3 (RH < 75 %) incl. salt spray acc. to EN 60068-2-52 (severity degree 3); *

— to mechanically active substances according to EN 60721-3-6

Yes; Class 6S3 incl. sand, dust; *

Yes; Class 6S3 incl. sand, dust; *

from supply voltage 1L+

— Note regarding classification of environmental conditions acc. to EN 60721

* The supplied plug covers must remain in place over the unused interfaces during operation!

* The supplied plug covers must remain in place over the unused interfaces during operation!

Operating systems

Operating systems

Windows Embedded Standard 7 E 32-bit

Configuration

Programming

Programming language

— LAD

Yes

— FBD

Yes

— STL

Yes

— SCL

Yes

— CFC

No

— GRAPH

Yes

Know-how protection

● User program protection/password protection

Yes

● Copy protection

Yes

● Block protection

Yes

Access protection

● Protection level: Write protection

Yes

● Protection level: Read/write protection

Yes

● Protection level: Complete protection

Yes

Cycle time monitoring

● lower limit

adjustable minimum cycle time

● upper limit

adjustable maximum cycle time

Open Development interfaces

● Size of ODK SO file, max.

3.8 Mbyte

Peripherals/Options

Peripherals

● SD card

Optionally for additional mass storage

Optionally for additional mass storage

Dimensions

Width

160 mm

160 mm

Height

117 mm

117 mm

Depth

75 mm

75 mm

Weights

Weight, approx.

0.83 kg

0.83 kg

固件版本为V1.0或更高的"TM Count 1x24V" 和 "TM PosInput 1" 模块可以在以下ET 200SP接口模块下使用:

工艺模块支持以下列出的操作模式:

注意

警告

该常问问题仅适用于 STEP 7 (TIA Portal) V13 以及更高版本,因为版本低于 V13 的STEP7 的工艺对象是无法使用的。

表1显示了总线模块,模块还有DP/PA Link模块以及Y Link模块的可能组合。

表1

1) 在使用旧的CP 443-5 时(文章编号: 6GK7443-5DX02-0XE0), 在自动化系统中执行 IM 157/IM 153-2 只能在总线模块6ES7-7HE80-0XA0以及配置6ES70AA81-0XA0结合时操作。

表2 展示的是总线模块,模块(PROFIBUS IM 153-2)和配置ET 200M的可能组合。

表 2

表3 展示的是总线模块,模块(PROFIBUS IM 153-2 FO)和配置ET 200M的可能组合。

表 3

表 4 显示的是哪个总线模块可以使用接口模块PROFIBUS IM153-1。

表 4

表5显示的是哪个总线模块可以使用接口模块IM 153-4。

表 5

以下手册中介绍了模块共享输入/输出(MSI/MSO)的基本信息。 SIMATIC PROFINET PROFINET with STEP 7 V13.

条目 ID 102325771包含了支持MSI/MSO功能的IO设备的概览。

这篇文档介绍了如何在STEP 7 (TIA Portal)中配置访问共享的设备及模块内部共享输入/输出功能。可以在两个不同的项目里或同一个项目里来配置IO 控制器。

按照以下步骤在同一个项目下配置两个CPU:

按照以下步骤在两个不同的项目下配置两个CPU:

列表价(不含增值税)

显示价格

您的单价(不含增值税)

显示价格

PDF 格式的数据表

下载

服务和支持 (手册,认证,问答...)

下载

产品

商品编号(市售编号)

6AG1677-2AA31-4EB0

产品说明

SIPLUS ET 200SP CPU 1515SP PC 4GB 0 ... +60 °C 带防腐蚀涂层 基于:6ES7677-2AA31-0EB0 。 CPU 1515SP PC. 4 GB RAM, 8 GB CFAST 带 预装 WES 7 E 32 Bit, 带 S7-1500 软件控制器 预装 CPU 1505SP V2.0, 接口: 1个 CFAST 插槽,1个 SD/MMC 插槽, 1个接口,用于 ET 200SP 总线 适配器 PROFINET, 1个 10/100/1000 MBit/s 以太网 , 3 个 USB,1 个 DVI-I,恢复盘 DVD 文档在 DVD 上,

产品家族

CPU 1515SP PC

产品生命周期 (PLM)

PM300:有效产品

价格数据

价格组 / 总部价格组

CT / 473

列表价(不含增值税)

显示价格

您的单价(不含增值税)

显示价格

金属系数

无

交付信息

出口管制规定

AL : N / ECCN : 5D992

工厂生产时间

22 天

净重 (Kg)

1.075 Kg

产品尺寸 (W x L X H)

未提供

包装尺寸

12.20 x 8.30 x 6.30

包装尺寸单位的测量

CM

数量单位

1 件

包装数量

1

其他产品信息

EAN

4047618081003

UPC

未提供

商品代码

85371091

LKZ_FDB/ CatalogID

A&DSE/SIP ADD

产品组

4257

原产国

德国

Compliance with the substance restrictions according to RoHS directive

RoHS 合规开始日期: 2017.03.02

产品类别

B: 受限的或中期重复使用性

电气和电子设备使用后的收回义务类别

没有电气和电子设备使用后回收的义务

分类

版本

分类

eClass

5.1

27-24-26-07

eClass

6

27-24-26-07

eClass

7.1

27-24-26-07

eClass

8

27-24-26-07

eClass

9

27-24-26-07

eClass

9.1

27-24-26-07

ETIM

5

EC001603

ETIM

6

EC001603

IDEA

4

3565

UNSPSC

15

32-15-17-05

概述

for separating Windows systems from control functions

Note

![]()

应用

![]()

设计

![]()

功能

SCL (IL), LAD, FBD, STL, GRAPH7 (SFC)

The real-time system of the integrated S7-1500 software controllers enables parallel, independent operation of Windows:

The CPU 1515SP PC ensures the security of plant data even when the power fails:

PROFINET IO RT/IRT, isochronous mode, IO controller, I-Device, media redundancy, PROFIenergy, PROFIBUS DP master

Scanning the CPU via the Web server is supported by all CPUs of the S7‑1500 automation system. The CPU Web server offers the following diagnostics options:

The trace function is supported by all CPUs of the S7-1500 automation system. It enables recording of analog and digital variables for each cycle and their representation as a curve with STEP 7. This is especially useful for Motion Control or closed-loop control applications

Universal PID or 3-step controller with integrated optimization. Integrated temperature controller.

System diagnostics can be displayed via a connected monitor, an HMI device, the Web server, or the operator panel of the software controller. Drive messages are also displayed in this way. System diagnostics are also available when the CPU is in STOP mode. If new hardware components are configured, the diagnostic inbation is updated automatically.

Algorithms and program blocks can be reliably password-protected against unauthorized access and modification.

Extended access protection provides comprehensive protection against unauthorized configuration changes. Various authorization levels are available for assigning separate rights to different user groups.

The system protects the data transferred to the CPU against unauthorized tampering. Modified or third-party transmission of engineering data are safely detected by the CPU.

![]()

技术规范

哪些接口模块和ET 200SP的CPU可以使用 "TM Count 1x24V" 和 "TM PosInput 1" 模块?

哪些总线模块是可以和ET 200M接口模块一起使用的?

总线模块

IM 157

模块 IM 157

模块 IM 153-2

配置/功能

6ES7157-0AA81-0XA0

6ES7157-0AA82-0XA0

6ES7153-2BA81-0XB0

6ES7153-2BA82-0XB0

6ES7153-2BA70-0XB0

6ES7195-7HE80-0XA0

是1)

是1)

是1)

是1)

否

6ES7157-0AA81-0XA0

6ES7195-7HD80-0XA0

否

是

是

是

否

6ES7157-0AA82-0XA0

否

否

是

是

是

6ES7153-2BA81-0XA0 及更高

总线模块

IM 153-2

IM 153-2 HF

配置/功能

6ES7153-2AA02-0XB0

6ES7153-2BA00-0XB0

6ES7153-2BA01-0XB0

6ES7153-2BA02-0XB0

6ES7153-2BA10-0XB0

6ES7195-7HA00-0XA0

是

是

是

是

是

6ES7153-2AA02-0XB0

否

是

是

是

是

6ES7153-2BA00-0XB0 及更高

6ES7195-7HD00-0XA0

是

是

是

是

否

6ES7153-2AA02-0XB0

6ES7195-7HD10-0XA0

否

是

是

是

是

6ES7153-2AA02-0XB0

否

是

是

是

是

6ES7153-2BA00-0XB0 及更高

总线模块

IM 153-2 FO

IM 153-2 FO HF

配置/功能

6ES7153-2AB00-0XB0

6ES7153-2AB01-0XB0

6ES7153-2BB00-0XB0

6ES7195-7HA00-0XA0

是

是

是

6ES7153-2AB00-0XB0

否

是

是

6ES7153-2AB01-0XB0

否

否

是

6ES7153-2BB00-0XB0

6ES7195-7HD00-0XA0

是

是

是

6ES7153-2AB00-0XB0

否

是

是

6ES7153-2AB01-0XB0

6ES7195-7HD10-0XA0

否

否

是

6ES7153-2AB00-0XB0

否

否

是

6ES7153-2AB01-0XB0

否

否

是

6ES7153-2BB00-0XB0

总线模块

IM 153-1

6ES7153-1AA00-0XB0

6ES7153-1AA01-0XB0

6ES7153-1AA02-0XB0

6ES7153-1AA03-0XB0

6ES7153-1AA82-0XB0

6ES7153-1AA83-0XB0

6ES7195-7HA00-0XA0

是

是

是

是

是

是

6ES7195-7HD00-0XA0

否

否

否

否

否

否

6ES7195-7HD10-0XA0

否

否

否

否

否

否

总线模块

IM 153-4 PN

IM 153-4 PN HF

6ES7153-4AA00-0XB0

6ES7153-4AA00-0XB0

6ES7153-4BA00-0XB0

6ES7195-7HA00-0XA0

是

是

是

6ES7195-7HD00-0XA0

否

否

否

6ES7195-7HD10-0XA0

否

否

否

如何在STEP 7 (TIA Portal)中配置访问共享的设备及模块内部共享输入/输出(MSI/MSO)功能?

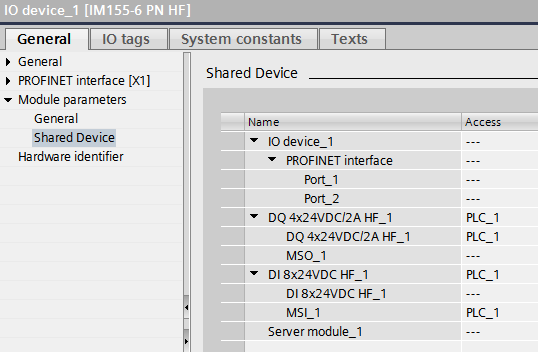

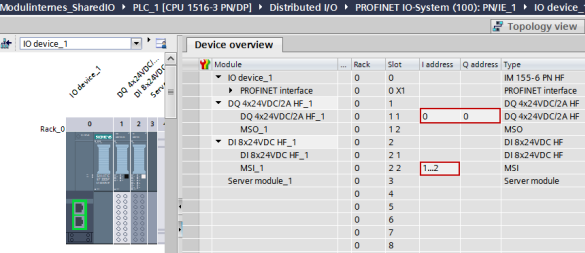

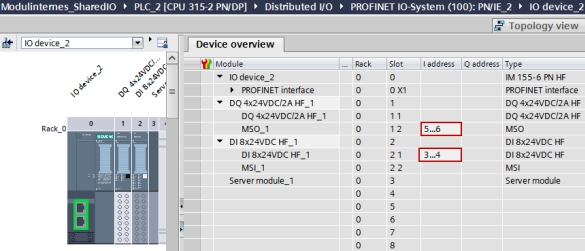

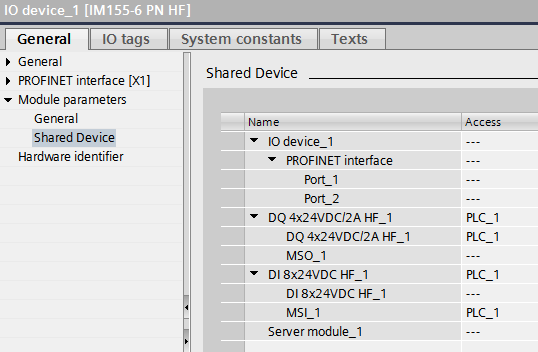

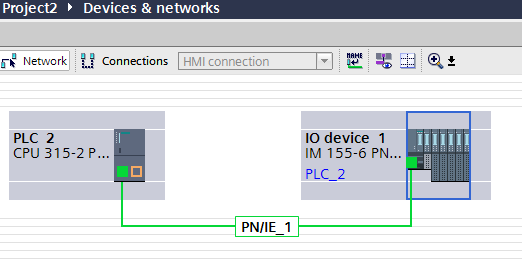

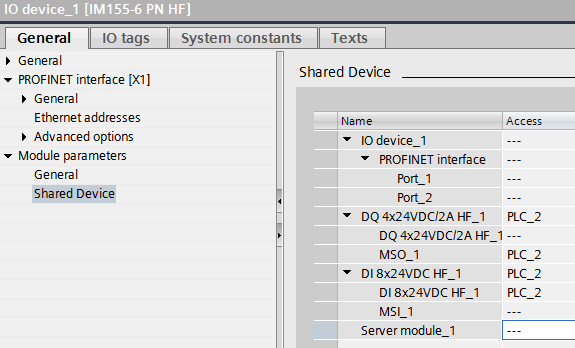

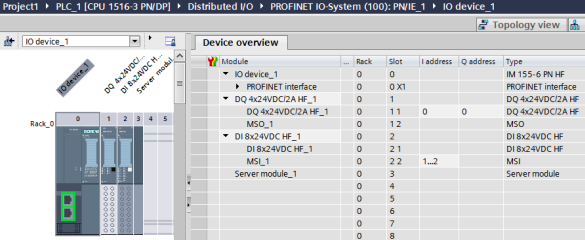

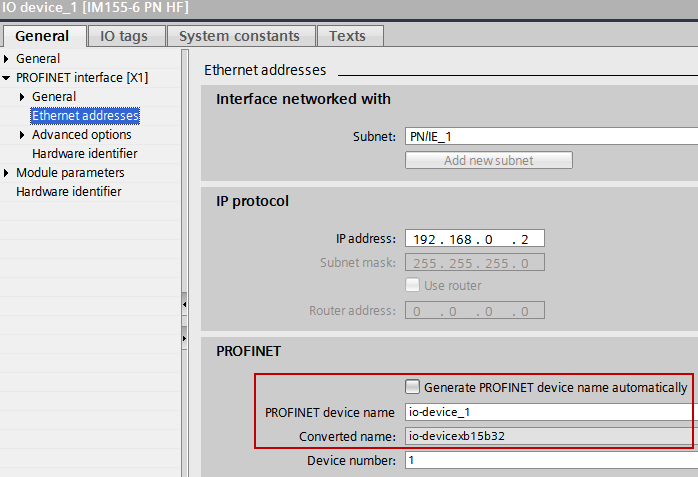

在这个例子里,一个S7-1500 CPU和一个S7-300 CPU作为IO控制器来访问作为共享设备的ET200SP的输入和输出数据。

一个输入模块和一个输出模块插到ET200SP的插槽中,S7-1500CPU将会读取输入和写入输出,S7-300CPU将会读取输入和输出。

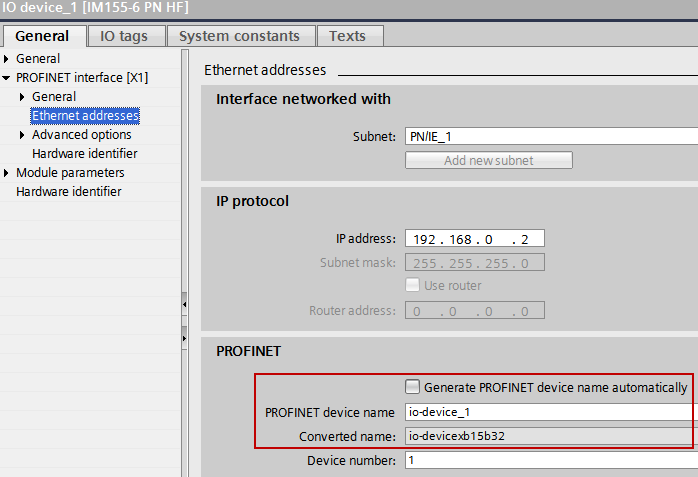

图. 1

在同一个项目下的配置

图. 2

图. 3

图. 4

图. 5

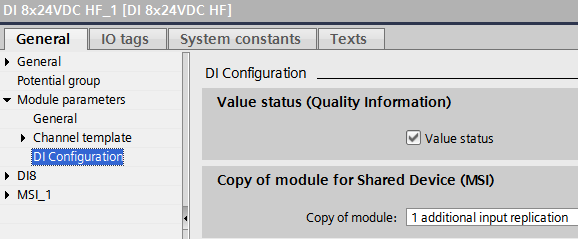

在例子里S7-1500CPU会被设置为输出,也就是说S7-1500(PLC1)可以访问输出模块的输出,因此对于S7-1500来说输出模块是一个基本模块。因此对于S7-1500来说输入模块是一个MSI模块。

提供给S7-300 (PLC_2)数据的模块或它们的副本不会分配给其他的IO控制器,不要将接口模块分配给任何的IO控制器。

图. 6

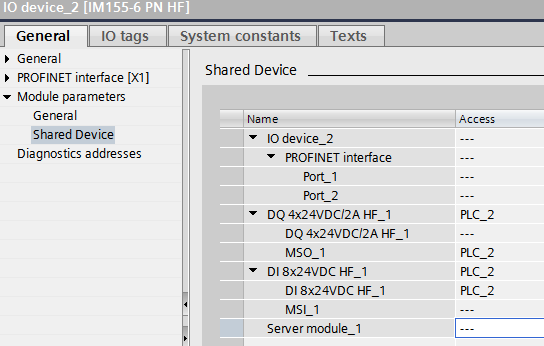

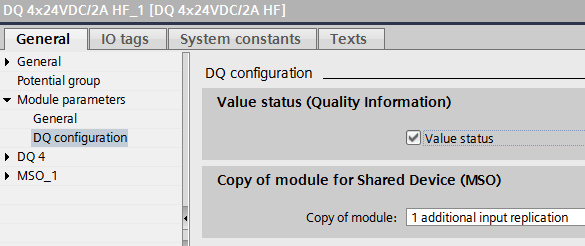

在例子里S7-300CPU管理输出模块的输出副本,也就是说S7-300(PLC2)可以访问输出模块的输出副本,因此对于S7-300来说输出模块是一个MSO模块。

S7-300(PLC2)访问输入模块的输入,因此对于S7-300来说输入模块是一个基本模块。

提供给S7-1500 (PLC_1)数据的模块或它们的副本不会分配给其他的IO控制器,

不要将接口模块分配给任何的IO控制器。

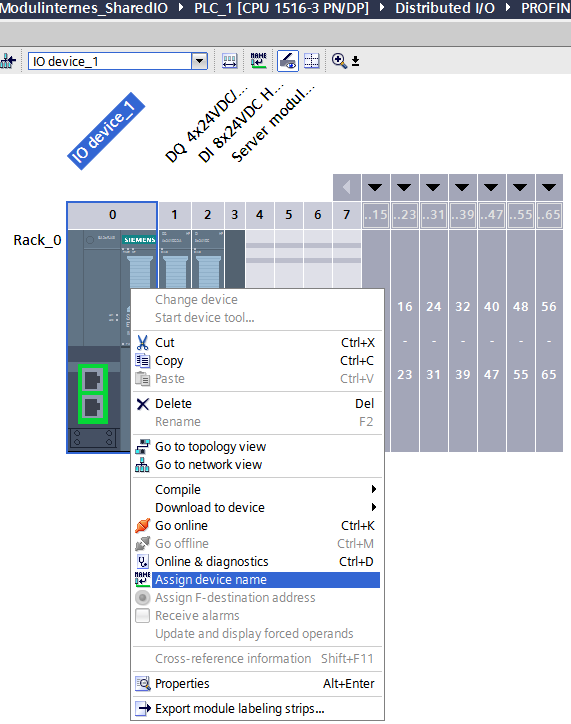

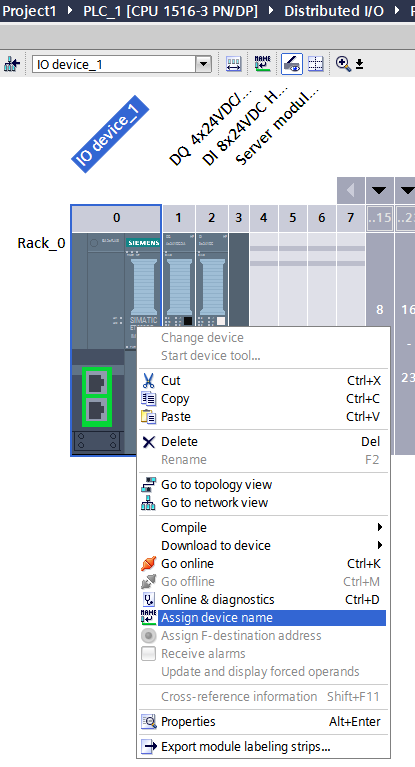

图. 7

图. 8

图. 9

图. 10

图. 11

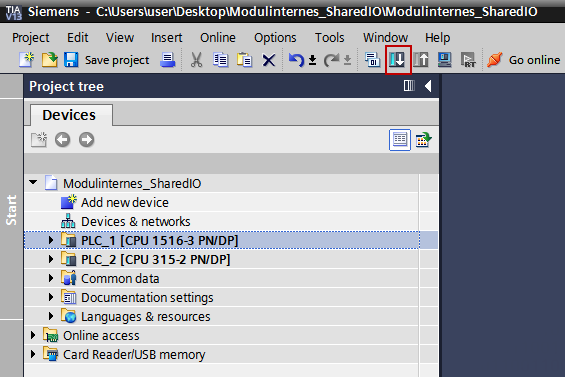

在两个不同项目下的配置

图. 12

图. 13

图. 14

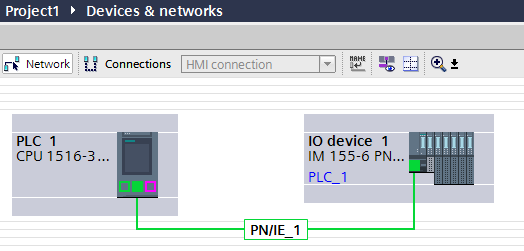

在例子里 S7-1500CPU 会被设置为输出,也就是说S7-1500可以访问输出模块的输出,因此对于S7-1500来说输出模块是一个基本模块。

S7-1500访问输入模块的输入副本,因此对于S7-1500来说输入模块是一个MSI模块。

提供给S7-300数据的模块或它们的副本不会分配给其他的IO控制器。

不要将接口模块分配给任何的IO控制器。

图. 15

图. 16

在例子里S7-300 CPU管理输出模块的输出副本,也就是说 S7-300 可以访问输出模块的输出副本,因此对于 S7-300 来说输出模块是一个MSO模块。

S7-300访问输入模块的输入,因此对于S7-300来说输入模块是一个基本模块。

提供给S7-1500数据的模块或它们的副本不会分配给其他的IO控制器,

不要将接口模块分配给任何的IO控制器。

图. 17

图. 18

图. 19

图. 20